Page 39 - MetalForming July 2012

P. 39

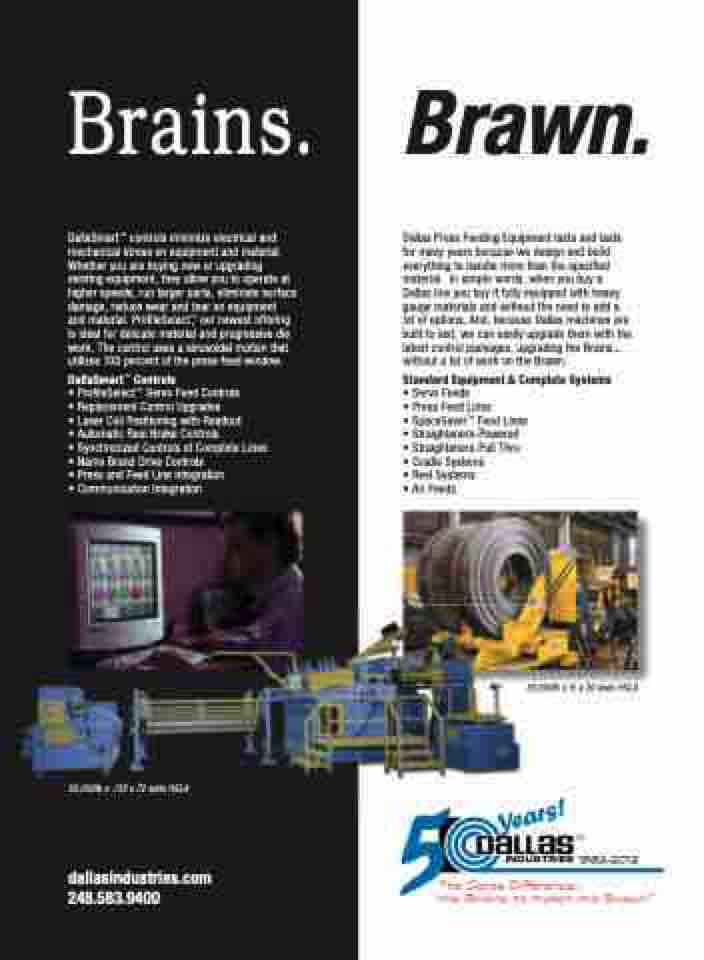

Brains.

DallaSmartTM controls minimize electrical and mechanical stress on equipment and material. Whether you are buying new or upgrading existing equipment, they allow you to operate at higher speeds, run larger parts, eliminate surface damage, reduce wear and tear on equipment

and material. ProfileSelectTM, our newest offering is ideal for delicate material and progressive die work. The control uses a sinusoidal motion that utilizes 100 percent of the press-feed window.

DallaSmartTM Controls

• ProfileSelectTM Servo Feed Controls

• Replacement Control Upgrades

• Laser Coil Positioning with Readout

• Automatic Reel Brake Controls

• Synchronized Controls of Complete Lines • Name Brand Drive Controls

• Press and Feed Line Integration

• Communication Integration

50,000lb x .135 x 72 wide HSLA

dallasindustries.com 248.583.9400

Brawn.

Dallas Press Feeding Equipment lasts and lasts for many years because we design and build everything to handle more than the specified material. In simple words, when you buy a Dallas line you buy it fully equipped with heavy gauge materials and without the need to add a lot of options. And, because Dallas machines are built to last, we can easily upgrade them with the latest control packages, upgrading the Brains... without a lot of work on the Brawn.

Standard Equipment & Complete Systems

• Servo Feeds

• Press Feed Lines

• SpaceSaverTM Feed Lines • Straighteners-Powered • Straighteners-Pull Thru • Cradle Systems

• Reel Systems

• Air Feeds

30,000lb x 1⁄2 x 20 wide HSLA

1962-2012