Page 30 - MetalForming April 2012

P. 30

New Nesting Software

Nets Quick ROI

“Metals Ready for Business” is the motto of service center Tampa Bay Steel, where new nesting software helps the firm boost quote accuracy and slash programming time for its variety of thermal-cutting machines.

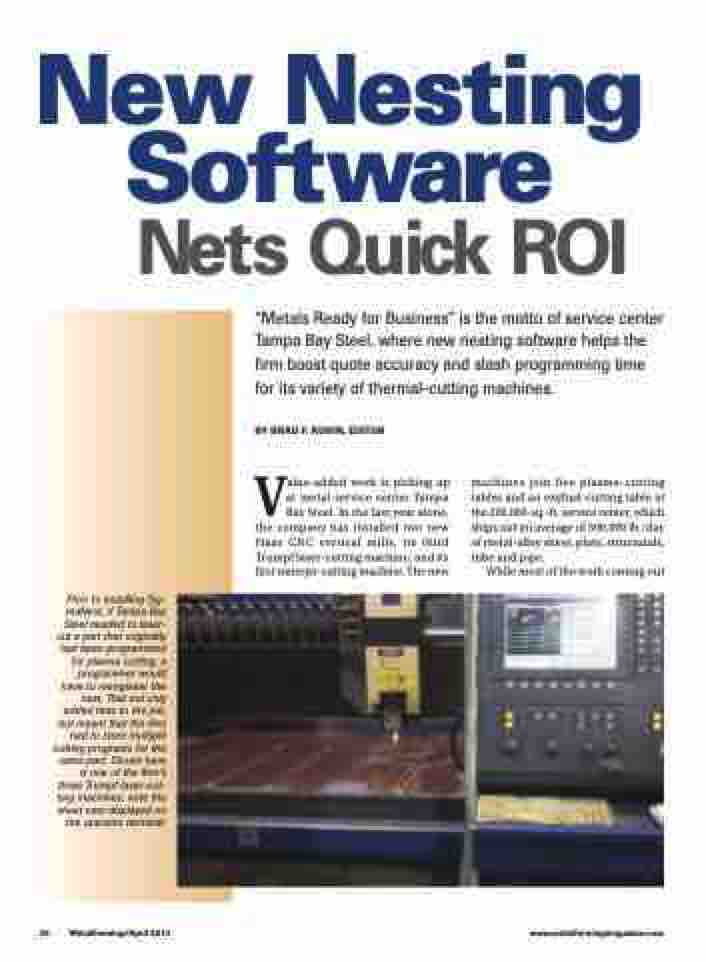

Prior to installing Sig-

maNest, if Tampa Bay Steel needed to laser- cut a part that originally had been programmed for plasma cutting, a programmer would have to reengineer the nest. That not only added time to the job, but meant that the firm had to store multiple cutting programs for the same part. Shown here is one of the firm’s three Trumpf laser-cut- ting machines; note the sheet nest displayed on the operator terminal.

BY BRAD F. KUVIN, EDITOR

Value-added work is picking up at metal-service center Tampa Bay Steel. In the last year alone, the company has installed two new Haas CNC vertical mills, its third Trumpf laser-cutting machine, and its first waterjet-cutting machine. The new

machines join five plasma-cutting tables and an oxyfuel-cutting table at the 200,000-sq.-ft. service center, which ships out an average of 300,000 lb./day of metal-alloy sheet, plate, structurals, tube and pipe.

While most of the work coming out

28 MetalForming/April 2012

www.metalformingmagazine.com