Page 10 - MetalForming December 2011

P. 10

Tech Update

Weld Simulation at Rolls Royce Models Complex Fabrication Processes

Realistic simulation with finite-ele- ment analysis (FEA) is a key tool used by design engineers at the Rolls-Royce Marine division in Derby, UK, tasked with quantifying and verifying welding procedures used in power plants and propulsion systems.

“Welds present a complex modeling problem requiring thermal and structur- al solutions,” says David Hodgson, a com- pany engineer. “We are looking to predict the distortion of components during manufacture, the position and magnitude of peak residual stresses and the effects of the welding process on the metals involved.”

Hodgson’s group has an ongoing research partnership with the Materials Science Center of The University of Man- chester, and UK consulting company Serco Assurance. Rolls-Royce, after eval-

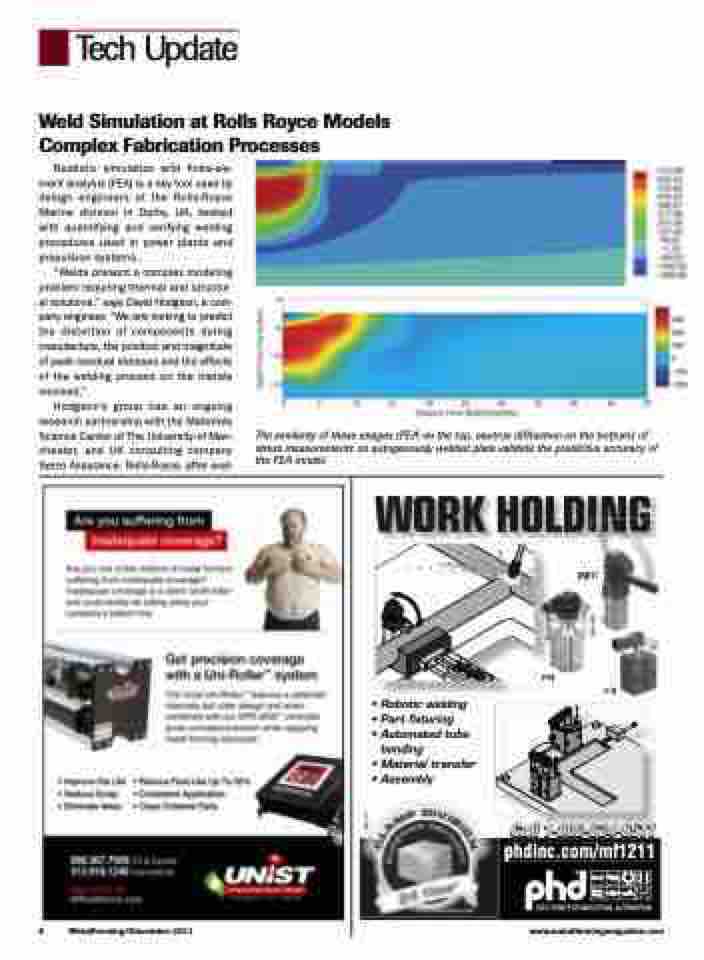

The similarity of these images (FEA on the top, neutron diffraction on the bottom) of stress measurements on autogenously welded plate validate the predictive accuracy of the FEA model.

8 MetalForming/December 2011

www.metalformingmagazine.com

• Robotic welding

• Part fixturing

• Automated tube

bending

• Material transfer

• Assembly

C

1

Ca

C

1

C

C

C

1

C

C

C

Ca

al

a

a

l

8

a

a

al

ll

l

l 1

ll 1-8

PE

B

P

1-8

80

00

0

800

0

0-

2

0

0

0

0-

phdinc.com/mf1211

-62

-

-6

62

24

2

2

2

2

24

4-8

4

4

8

4

4

4-8

85

8

8

51

5

5

5

5

51

1

1

1

1

1

1

1