Page 40 - MetalForming September 2011

P. 40

Tooling Technology

The Modern-Day Die Setter

Professionalism in any field requires continuous improve- ment of knowledge and work habits. There simply is no substitute for good work habits. Shortcuts intended to make a job easier soon become bad habits. And specifically in the press- room, shortcuts taken during die setup can lead to catastrophic damage to dies and presses, as well as serious or fatal injury to press operators or other pressroom personnel.

Historically, shops expected their die setters to set up each die and help train press operators on how to produce quality stampings using safe operat- ing practices. Today’s die setters, how- ever, have become talented and multi- skilled technicians. They do everything from setting up and running unat- tended press operations to perform- ing equipment maintenance, part- quality assessments and simple die-repair tasks.

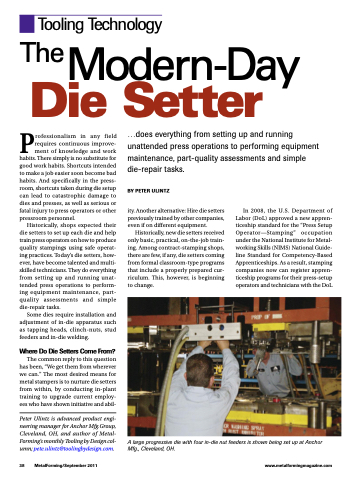

Some dies require installation and adjustment of in-die apparatus such as tapping heads, clinch-nuts, stud feeders and in-die welding.

Where Do Die Setters Come From?

The common reply to this question has been, “We get them from wherever we can.” The most desired means for metal stampers is to nurture die setters from within, by conducting in-plant training to upgrade current employ- ees who have shown initiative and abil-

Peter Ulintz is advanced product engi- neering manager for Anchor Mfg.Group, Cleveland, OH, and author of Metal- Forming’s monthly Tooling by Design col- umn; pete.ulintz@toolingbydesign.com.

...does everything from setting up and running unattended press operations to performing equipment maintenance, part-quality assessments and simple die-repair tasks.

BY PETER ULINTZ

ity. Another alternative: Hire die setters previously trained by other companies, even if on different equipment.

Historically, new die setters received only basic, practical, on-the-job train- ing. Among contract-stamping shops, there are few, if any, die setters coming from formal classroom-type programs that include a properly prepared cur- riculum. This, however, is beginning to change.

In 2008, the U.S. Department of Labor (DoL) approved a new appren- ticeship standard for the “Press Setup Operator—Stamping” occupation under the National Institute for Metal- working Skills (NIMS) National Guide- line Standard for Competency-Based Apprenticeships. As a result, stamping companies now can register appren- ticeship programs for their press-setup operators and technicians with the DoL

38 MetalForming/September 2011

www.metalformingmagazine.com

A large progressive die with four in-die nut feeders is shown being set up at Anchor Mfg., Cleveland, OH.