Page 7 - MetalForming June 2011

P. 7

Phygen’s New Large Tool Coating Chamber—

Just What

Pentaflex Ordered

Pentaflex, Springfield, OH, stamps and assembles components primarily for the tractor-trailer industry. New federal regulations governing air quality and emissions have brought new work for semi-tractor exhaust units.

“These deep-drawn stainless-steel parts

are very large, with draws from 8 to 10 in.,” explains Michael Stull, Pentaflex tooling manager. Stull, a fan of Phygen Coating’s FortiPhy tool coating process since first

using it seven years ago, is very happy with

the new Phygen coating chamber size and ability to coat up to 3 times larger parts. Details used to produce his parts are very large too plus the larger chambers handle these details and keep Pentaflex’s stamping lines running.

“The FortiPhy coatings protect our tool details run after run after run,” he says. “When they need service, we ship them to Phygen to be cleaned up and recoated, and they go right back into service. We have not had to replace them.”

Quick Turnaround

“Phygen is the best supplier as far as supplying

us with a very high quality product in a very, very short lead time, says Stull. “In some cases we can overnight tooling and Phygen will have it back to us in two to three days. Phygen does an excellent job of scheduling, and keeps us up and running.”

For the full story visit: www.phygen.com/Success_Pentaflex_LargeParts.html

How FortiPhy Works – This PVD UltraEndurance coating process creates

a dense nanocrystalline coating with up to 90% fewer defects in the coating structure than conventional PVD coatings. FortiPhy sticks best

to tools achieving super adhesion – even better than a “HOT” process. It is applied at half the temperature and below the high tempering point of D-2.

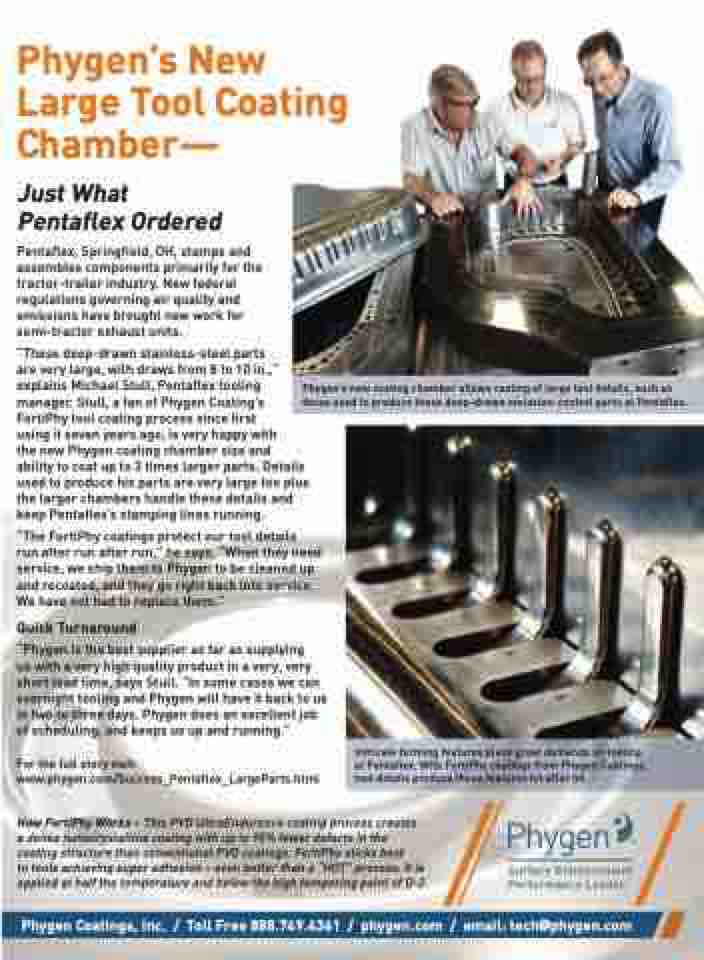

Phygen’s new coating chamber allows coating of large tool details, such as those used to produce these deep-drawn emission-control parts at Pentaflex.

Intricate forming features place great demands on tooling at Pentaflex. With FortiPhy coatings from Phygen Coatings, tool details produce these features hit after hit.

Phygen Coatings, Inc. / Toll Free 888.749.4361 / phygen.com / email: tech@phygen.com