Page 45 - MetalForming April 2011

P. 45

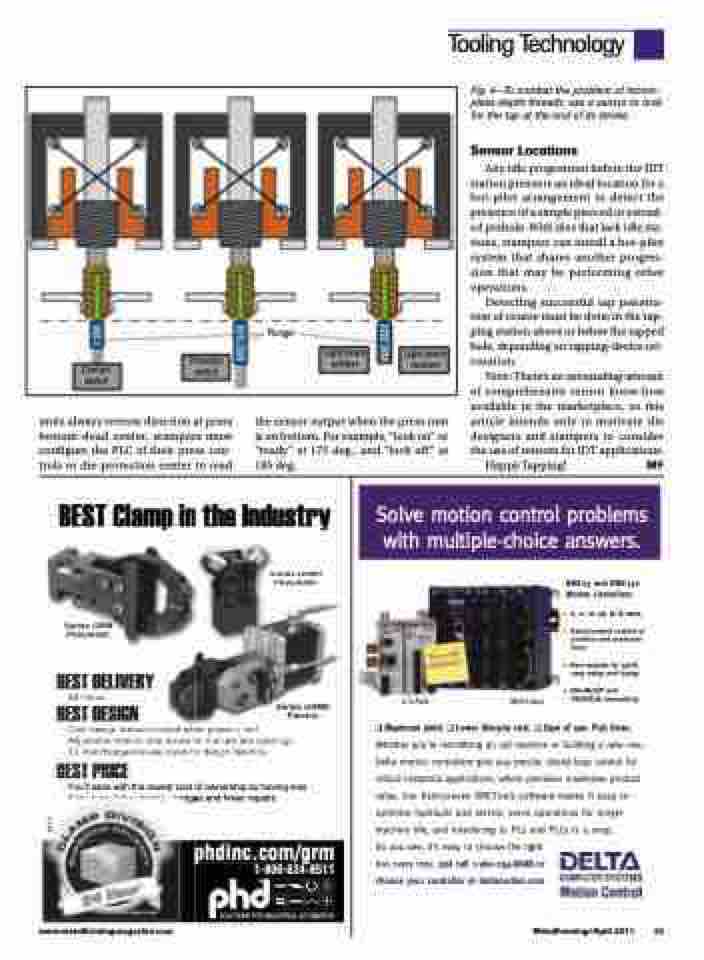

Contact switch

Proximity switch

Light beam emitter

Light beam receiver

units always reverse direction at press bottom-dead center, stampers must configure the PLC of their press con- trols or die-protection center to read

the sensor output when the press ram is on bottom. For example, “look on” or “ready” at 175 deg., and “look off” at 185 deg.

BEST Clamp in the Industry

- You’ll save with the lowest cost of ownership by having less down time faster tooling changes and fewer repairs

phdinc.com/grm 1-800-624-8511

����� ������ ������� �������� ���� ��������������� ��������

www.metalformingmagazine.com

MetalForming/April 2011 43

Plunger

Fig. 4—To combat the problem of incom- plete-depth threads, use a sensor to look for the tap at the end of its stroke.

Sensor Locations

Any idle progression before the IDT station presents an ideal location for a hot-pilot arrangement to detect the presence of a simple pierced or extrud- ed prehole. With dies that lack idle sta- tions, stampers can install a hot-pilot system that shares another progres- sion that may be performing other operations.

Detecting successful tap penetra- tion of course must be done in the tap- ping station above or below the tapped hole, depending on tapping-device ori- entation.

Note: There’s an astounding amount of comprehensive sensor know-how available in the marketplace, so this article intends only to motivate die designers and stampers to consider the use of sensors for IDT applications.

Happy Tapping! MF

��� ����

����������

����� ��� ������ ������ �����������

� �� �� �� �� �� � ����

� ������������ ������� �� �������� ��� ��������� �����

� ��� ������� ��� ������ ���� ����� ��� ������

� ����������� ��� �������� ������������

Tooling Technology

� ������� ������ � ����� ��������� ����� � ���� �� ���� ���� ������ ������� ������ ������������ �� ��� ������� �� �������� � ��� ���� ����� ������ ����������� ���� ��� ������� ����������� ������� ��� �������� ���������� ������������� ����� ��������� ��������� ������� ������ ��� ������������ �������� �������� ����� �� ���� �� �������� ��������� ��� �������� ����� ���������� ��� ������ ������� ����� ��� ����������� �� ��� ��� ���� �� � �����

�� ��� ���� ���� ���� �� ������ ��� ����� ��� ����� ����� ���� ���� �������������� �� ������ ���� ���������� �� ���������������