Page 42 - MetalForming April 2011

P. 42

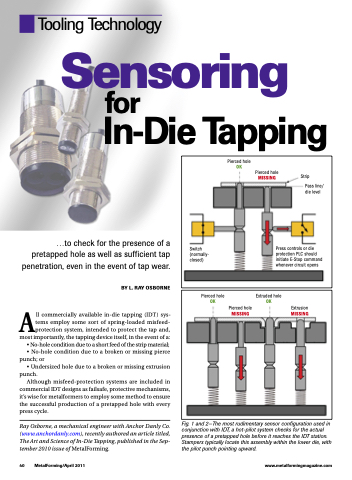

Switch (normally- closed)

Press controls or die protection PLC should initiate E-Stop command whenever circuit opens

Pierced hole

OK

Pierced hole

MISSING

Strip

Pass line/ die level

Pierced hole

OK

Extruded hole

OK

Pierced hole

MISSING

Extrusion

MISSING

Tooling Technology

Sensoring

for

In-Die Tapping

...to check for the presence of a pretapped hole as well as sufficient tap penetration, even in the event of tap wear.

BY L. RAY OSBORNE

All commercially available in-die tapping (IDT) sys- tems employ some sort of spring-loaded misfeed- protection system, intended to protect the tap and, most importantly, the tapping device itself, in the event of a:

• No-hole condition due to a short feed of the strip material;

• No-hole condition due to a broken or missing pierce punch; or

• Undersized hole due to a broken or missing extrusion punch.

Although misfeed-protection systems are included in commercial IDT designs as failsafe, protective mechanisms, it’s wise for metalformers to employ some method to ensure the successful production of a pretapped hole with every press cycle.

Ray Osborne, a mechanical engineer with Anchor Danly Co. (www.anchordanly.com), recently authored an article titled, The Art and Science of In-Die Tapping, published in the Sep- tember 2010 issue of MetalForming.

Fig. 1 and 2—The most rudimentary sensor configuration used in conjunction with IDT, a hot-pilot system checks for the actual presence of a pretapped hole before it reaches the IDT station. Stampers typically locate this assembly within the lower die, with the pilot punch pointing upward.

40 MetalForming/April 2011

www.metalformingmagazine.com