Page 21 - MetalForming March 2011

P. 21

Powerful

Powerful

Cleaning—

Cleaning—

But Not Too Clean

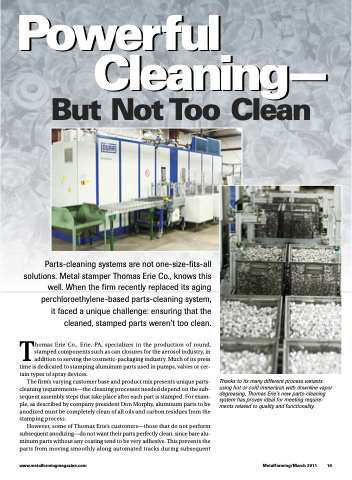

Parts-cleaning systems are not one-size-fits-all solutions. Metal stamper Thomas Erie Co., knows this well. When the firm recently replaced its aging

perchloroethylene-based parts-cleaning system, it faced a unique challenge: ensuring that the cleaned, stamped parts weren’t too clean.

Thomas Erie Co., Erie, PA, specializes in the production of round, stamped components such as can closures for the aerosol industry, in addition to serving the cosmetic-packaging industry. Much of its press time is dedicated to stamping aluminum parts used in pumps, valves or cer- tain types of spray devices.

The firm’s varying customer base and product mix presents unique parts- cleaning requirements—the cleaning processes needed depend on the sub- sequent assembly steps that take place after each part is stamped. For exam- ple, as described by company president Don Morphy, aluminum parts to be anodized must be completely clean of all oils and carbon residues from the stamping process.

However, some of Thomas Erie’s customers—those that do not perform subsequent anodizing—do not want their parts perfectly clean, since bare alu- minum parts without any coating tend to be very adhesive. This prevents the parts from moving smoothly along automated tracks during subsequent

Thanks to its many different process variants using hot or cold immersion with downline vapor degreasing, Thomas Erie’s new parts-cleaning system has proven ideal for meeting require- ments related to quality and functionality.

www.metalformingmagazine.com

MetalForming/March 2011 19