Page 33 - MetalForming February 2011

P. 33

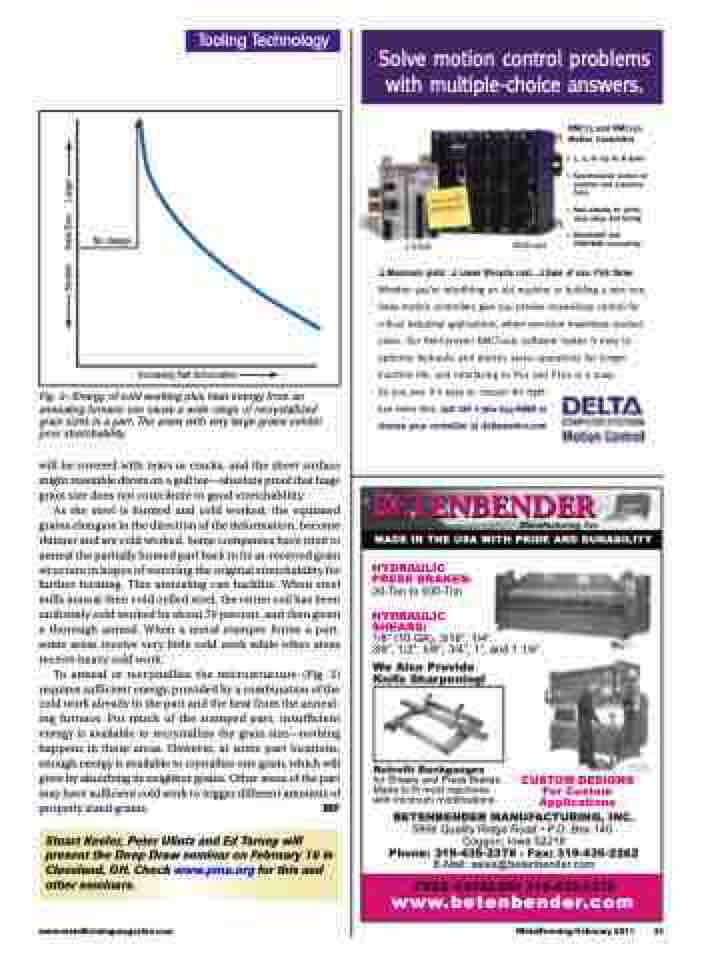

Fig. 2—Energy of cold working plus heat energy from an annealing furnace can cause a wide range of recrystallized grain sizes in a part. The areas with very large grains exhibit poor stretchability.

will be covered with tears or cracks, and the sheet surface might resemble divots on a golf tee—absolute proof that huge grain size does not contribute to good stretchability.

As the steel is formed and cold worked, the equiaxed grains elongate in the direction of the deformation, become thinner and are cold worked. Some companies have tried to anneal the partially formed part back to its as-received grain structure in hopes of restoring the original stretchability for further forming. This annealing can backfire. When steel mills anneal their cold-rolled steel, the entire coil has been uniformly cold worked by about 70 percent, and then given a thorough anneal. When a metal stamper forms a part, some areas receive very little cold work while other areas receive heavy cold work.

To anneal or recrystallize the microstructure (Fig. 2) requires sufficient energy, provided by a combination of the cold work already in the part and the heat from the anneal- ing furnace. For much of the stamped part, insufficient energy is available to recrystallize the grain size—nothing happens in those areas. However, at some part locations, enough energy is available to crystallize one grain, which will grow by absorbing its neighbor grains. Other areas of the part may have sufficient cold work to trigger different amounts of properly sized grains. MF

Stuart Keeler, Peter Ulintz and Ed Tarney will present the Deep Draw seminar on February 16 in Cleveland, OH. Check www.pma.org for this and other seminars.

� ������� ������ � ����� ��������� ����� � ���� �� ���� ���� ������ ������� ������ ������������ �� ��� ������� �� �������� � ��� ���� ����� ������ ����������� ���� ��� ������� ����������� ������� ��� �������� ���������� ������������� ����� ��������� ��������� ������� ������ ��� ������������ �������� �������� ����� �� ���� �� �������� ��������� ��� �������� ����� ���������� ��� ������ ������� ����� ��� ����������� �� ��� ��� ���� �� � �����

�� ��� ���� ���� ���� �� ������ ��� ����� ��� ����� ����� ���� ���� �������������� �� ������ ���� ���������� �� ���������������

Tooling Technology

No change

Increasing Part Deformation

��� ����

����������

����� ��� ������ ������ �����������

� �� �� �� �� �� � ����

� ������������ ������� �� �������� ��� ��������� �����

� ��� ������� ��� ������ ���� ����� ��� ������

� ����������� ��� �������� ������������

BETENBENDER Manufacturing, Inc.

MADE IN THE USA WITH PRIDE AND DURABILITY

HYDRAULIC PRESS BRAKES: 20-Ton to 500-Ton

HYDRAULIC

SHEARS:

���� ��� ���� ������ �����

����� ����� ����� ����� ��� ��� � �����

We Also Provide Knife Sharpening!

Retrofit Backgauges

��� ������ ��� ����� ������� ���� �� ��� ���� �������� ���� ������� ��������������

CUSTOM DESIGNS For Custom Applications

BETENBENDER MANUFACTURING, INC.

���� ������� ����� ���� � ���� ��� ��� ������� ���� �����

Phone: 319-435-2378 - Fax: 319-435-2262 ������� ���������������������

FREE CATALOG! 319-435-2378

www.betenbender.com

www.metalformingmagazine.com

MetalForming/February 2011 31

����� ������ ������� �������� ���� ��������������� ��������

Smaller Grain Size Larger