Page 69 - MetalForming October 2010

P. 69

Same as “D” diameter

D

Fig. 2

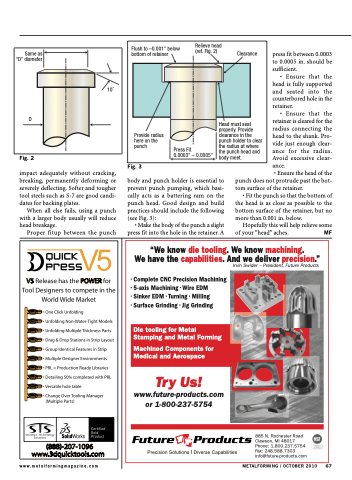

Flush to –0.001" below bottom of retainer

Relieve head (ref. Fig. 2)

press fit between 0.0003 to 0.0005 in. should be sufficient.

• Ensure that the head is fully supported and seated into the counterbored hole in the retainer.

• Ensure that the retainer is cleared for the radius connecting the head to the shank. Pro- vide just enough clear- ance for the radius. Avoid excessive clear- ance.

impact adequately without cracking, breaking, permanently deforming or severely deflecting. Softer and tougher tool steels such as S-7 are good candi- dates for backing plates.

When all else fails, using a punch with a larger body usually will reduce head breakage.

Proper fitup between the punch

body and punch holder is essential to prevent punch pumping, which basi- cally acts as a battering ram on the punch head. Good design and build practices should include the following (see Fig. 3):

• Make the body of the punch a slight press fit into the hole in the retainer. A

• Ensure the head of the punch does not protrude past the bot-

tom surface of the retainer.

• Fit the punch so that the bottom of

the head is as close as possible to the bottom surface of the retainer, but no more than 0.001 in. below.

Hopefully this will help relieve some of your “head” aches. MF

www.metalformingmagazine.com

METALFORMING / OCTOBER 2010 67

10˚

Clearance

Head must seat properly. Provide clearance in the punch holder to clear the radius at where the punch head and body meet.

Provide radius here on the punch

Fig. 3

Press Fit

0.0003" – 0.0005"

“We know die tooling. We know machining.

We have the capabilities. And we deliver precision.”

• Complete CNC Precision Machining • 5-axis Machining • Wire EDM

• Sinker EDM • Turning • Milling

• Surface Grinding • Jig Grinding

Die tooling for Metal Stamping and Metal Forming

Machined Components for Medical and Aerospace

Try Us!

www.future-products.com or 1-800-237-5754

Irvin Swider – President, Future Products

885 N. Rochester Road Clawson, MI 48017 Phone: 1.800.237.5754 Fax: 248.588.7303 info@future-products.com