Page 63 - MetalForming October 2010

P. 63

Adjustable Stock Adjustable Upper &

Guide Option

Lower Nozzles

Lube Collection

The Pax Spray Cabinet is an ideal solution for lubricating stock prior to entering the die area. It is designed with adjustable, built-in spray nozzles and can be mounted directly onto feeds or to the press.

4" Cabinet Mounts On Bolster

SPRAY CABINETS

PAX PRODUCTS, INC.

Contact Pax Regarding In-Die Lubrication

www.paxproducts.com

0.3

0.2

n

0.1

B

A

0

0 50 100

Yield Stress (KSI)

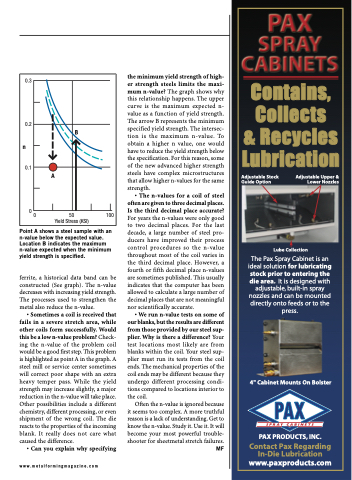

Point A shows a steel sample with an n-value below the expected value. Location B indicates the maximum n-value expected when the minimum yield strength is specified.

ferrite, a historical data band can be constructed (See graph). The n-value decreases with increasing yield strength. The processes used to strengthen the metal also reduce the n-value.

• Sometimes a coil is received that fails in a severe stretch area, while other coils form successfully. Would this be a low n-value problem? Check- ing the n-value of the problem coil would be a good first step. This problem is highlighted as point A in the graph. A steel mill or service center sometimes will correct poor shape with an extra heavy temper pass. While the yield strength may increase slightly, a major reduction in the n-value will take place. Other possibilities include a different chemistry, different processing, or even shipment of the wrong coil. The die reacts to the properties of the incoming blank. It really does not care what caused the difference.

• Can you explain why specifying

the minimum yield strength of high- er strength steels limits the maxi- mum n-value? The graph shows why this relationship happens. The upper curve is the maximum expected n- value as a function of yield strength. The arrow B represents the minimum specified yield strength. The intersec- tion is the maximum n-value. To obtain a higher n value, one would have to reduce the yield strength below the specification. For this reason, some of the new advanced higher strength steels have complex microstructures that allow higher n-values for the same strength.

• The n-values for a coil of steel often are given to three decimal places. Is the third decimal place accurate? For years the n-values were only good to two decimal places. For the last decade, a large number of steel pro- ducers have improved their process control procedures so the n-value throughout most of the coil varies in the third decimal place. However, a fourth or fifth decimal place n-values are sometimes published. This usually indicates that the computer has been allowed to calculate a large number of decimal places that are not meaningful nor scientifically accurate.

• We run n-value tests on some of our blanks, but the results are different from those provided by our steel sup- plier. Why is there a difference? Your test locations most likely are from blanks within the coil. Your steel sup- plier must run its tests from the coil ends. The mechanical properties of the coil ends may be different because they undergo different processing condi- tions compared to locations interior to the coil.

Often the n-value is ignored because it seems too complex. A more truthful reason is a lack of understanding. Get to know the n-value. Study it. Use it. It will become your most powerful trouble- shooter for sheetmetal stretch failures.

www.metalformingmagazine.com

MF