Page 35 - MetalForming July 2009

P. 35

_

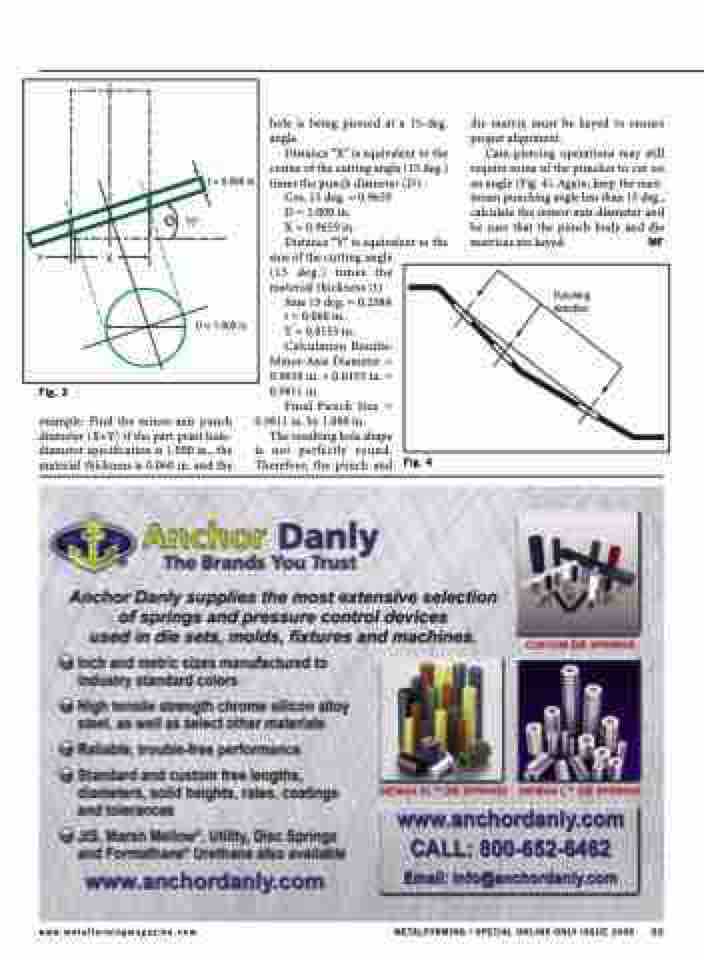

t = 0.060 in.

15°

D = 1.000 in.

YX

hole is being pierced at a 15-deg. angle.

Distance “X” is equivalent to the cosine of the cutting angle (15 deg.) times the punch diameter (D).

Cos. 15 deg. = 0.9659

D = 1.000 in.

X = 0.9659 in.

Distance “Y” is equivalent to the

die matrix must be keyed to ensure proper alignment.

Cam-piercing operations may still require some of the punches to cut on an angle (Fig. 4). Again, keep the max- imum punching angle less than 15 deg., calculate the minor-axis diameter and be sure that the punch body and die matrices are keyed. MF

Punching direction

Fig. 3

example: Find the minor-axis punch diameter (X+Y) if the part print hole- diameter specification is 1.000 in., the material thickness is 0.060 in. and the

sine of the cutting angle (15 deg.) times the material thickness (t)

Sine 15 deg. = 0.2588 t = 0.060 in.

Y = 0.0155 in. Calculation Results:

Minor-Axis Diameter = 0.9659 in. + 0.0155 in. = 0.9811 in.

Final Punch Size = 0.9811 in. by 1.000 in.

The resulting hole shape is not perfectly round. Therefore, the punch and

Fig. 4

www.metalformingmagazine.com

METALFORMING / SPECIAL ONLINE-ONLY ISSUE 2009 33