Page 40 - MetalForming December 2016

P. 40

The Science of Forming By Stuart Keeler

n-Values Differ for

Advanced High-Strength Steels

0.3

0.2

0.1

0

200 400 600 Engineering Yield Strength (MPa)

HSLA

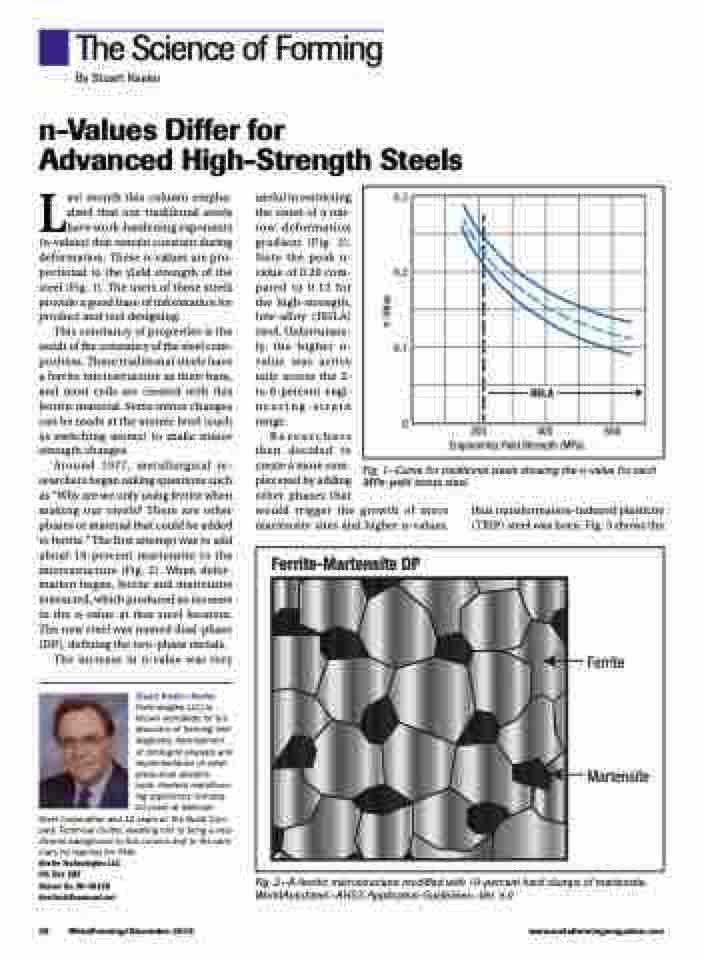

Last month this column empha- sized that our traditional steels have work-hardening exponents (n-values) that remain constant during deformation. These n-values are pro- portional to the yield strength of the steel (Fig. 1). The users of these steels provide a good base of information for product and tool designing.

This constancy of properties is the result of the constancy of the steel com- position. These traditional steels have a ferrite microstructure as their base, and most coils are created with this ferritic material. Some minor changes can be made at the atomic level (such as switching atoms) to make minor strength changes.

Around 1977, metallurgical re- searchers began asking questions such as “Why are we only using ferrite when making our steels? There are other phases or material that could be added to ferrite.” The first attempt was to add about 10-percent martensite to the microstructure (Fig. 2). When defor- mation began, ferrite and martensite interacted, which produced an increase in the n-value at that steel location. The new steel was named dual-phase (DP), defining the two-phase metals.

The increase in n-value was very

Stuart Keeler (Keeler Technologies LLC) is known worldwide for his discovery of forming limit diagrams, development of circle-grid analysis and implementation of other press-shop analysis tools. Keeler’s metalform- ing experience includes 24 years at National

Steel Corporation and 12 years at The Budd Com- pany Technical Center, enabling him to bring a very diverse background to this column and to the sem- inars he teaches for PMA.

Keeler Technologies LLC P.O. Box 283

Grosse Ile, MI 48138 keeltech@comcast.net

useful in restricting the onset of a nar- row deformation gradient (Fig. 3). Note the peak n- value of 0.20 com- pared to 0.13 for the high-strength, low-alloy (HSLA) steel. Unfortunate- ly, the higher n- value was active only across the 2- to 8-percent engi- neering-strain range.

Researchers

then decided to

create a more com-

plex steel by adding

other phases that

would trigger the

martensite sites and higher n-values,

Fig. 1—Curve for traditional steels showing the n-value for each MPa-yield-stress steel.

growth of more

thus transformation-induced plasticity (TRIP) steel was born. Fig. 3 shows the

Ferrite-Martensite DP

Ferrite

Martensite

38 MetalForming/December 2016

www.metalformingmagazine.com

Fig. 2—A ferritic microstructure modified with 10-percent hard clumps of martensite. WorldAutoSteel—AHSS Application Guidelines—Ver. 5.0

n-Value