Page 30 - MetalForming December 2016

P. 30

Tips for

Maintaining Your Waterjet System

Improper maintenance of waterjet systems can cause inaccurate production, increased use of consumables and, most importantly, machine failure. Here’s some sound advice to keep your systems cutting accurately and productively.

BY MATT MCGREW

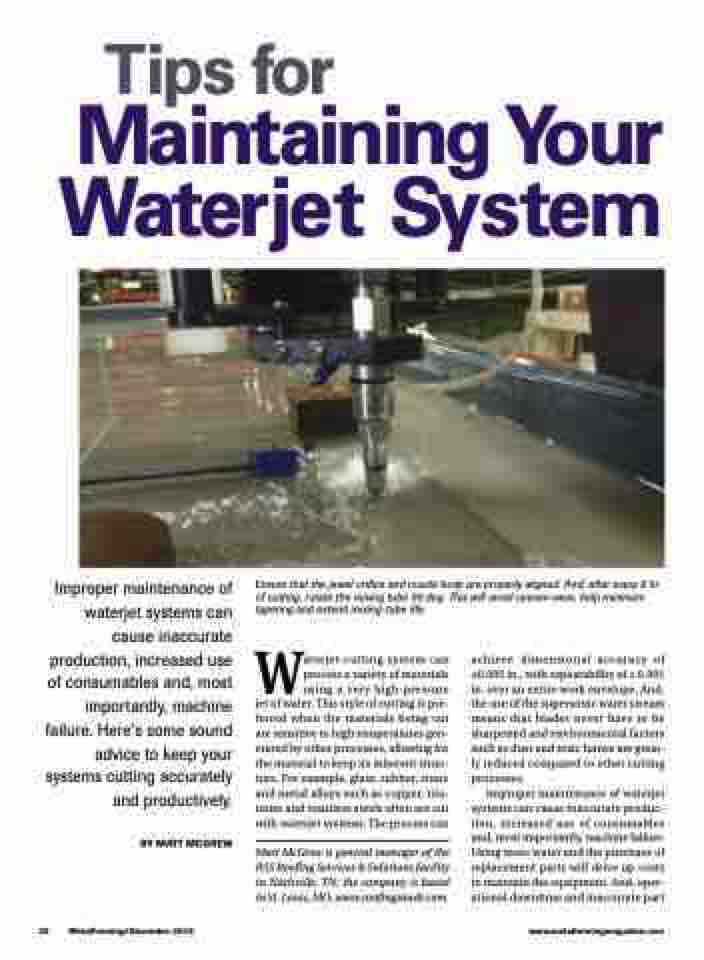

Ensure that the jewel orifice and nozzle body are properly aligned. And, after every 8 hr. of cutting, rotate the mixing tube 90 deg. This will avoid uneven wear, help minimize tapering and extend mixing-tube life.

Waterjet-cutting system can process a variety of materials using a very high-pressure jet of water. This style of cutting is pre- ferred when the materials being cut are sensitive to high temperatures gen- erated by other processes, allowing for the material to keep its inherent struc- ture. For example, glass, rubber, stone and metal alloys such as copper, tita- nium and stainless steels often are cut with waterjet systems. The process can

Matt McGrew is general manager of the RSS Roofing Services & Solutions facility in Nashville, TN; the company is based in St. Louis, MO, www.roofingsands.com.

achieve dimensional accuracy of ±0.005 in., with repeatability of ± 0.001 in. over an entire work envelope. And, the use of the supersonic water stream means that blades never have to be sharpened and environmental factors such as dust and toxic fumes are great- ly reduced compared to other cutting processes.

Improper maintenance of waterjet systems can cause inaccurate produc- tion, increased use of consumables and, most importantly, machine failure. Using more water and the purchase of replacement parts will drive up costs to maintain the equipment. And, oper- ational downtime and inaccurate part

28 MetalForming/December 2016

www.metalformingmagazine.com