Page 26 - MetalForming June 2019

P. 26

FABRICATION

DoThisina

CNC

Punching

Machine?

You bet! Tool technology enables a variety of actions once thought viable only in stamping presses or press brakes, or as secondary operations.

BY LOUIS A. KREN, SENIOR EDITOR

Imagine a game show with various pieces of equipment on stage: a stamping press, press brake, numer- ous single-operation machines and a CNC punching machine. The show’s premise: Given a part feature, decide which piece of equipment can do the job. The host shouts out a feature:

“90-deg. bend and beyond!”

“Well, Bob, for the right workpiece shape and size, part volume and feature height, a CNC punching machine can do that!” you answer.

Ding-Ding!

“You are correct! Now show me hinges!”

“I can with a CNC punching machine, Bob!”

Ding-Ding!

“Threaded holes in thin material!” “Ditto, Bob!”

Ding-Ding!

It’s bedlam, and before you know

it, you’re in the bonus round. In fact, CNC punching machines, with

the right tooling,

can perform a variety of

operations traditionally con-

sidered as press or press-brake work, or performed as secondary work in standalone stations. To explore such operations, MetalForming talked to Susan Erler, product manager of punching at Wilson Tool International (www.wilsontool.com), a provider of tooling technology for fabricating equipment.

90-Deg. Bends and Beyond

Typically, 90-deg. bends bring to mind press brakes. But, according to Erler, many manufacturers don’t realize that they can execute these bends in a punching machine. Achieving 90-deg.

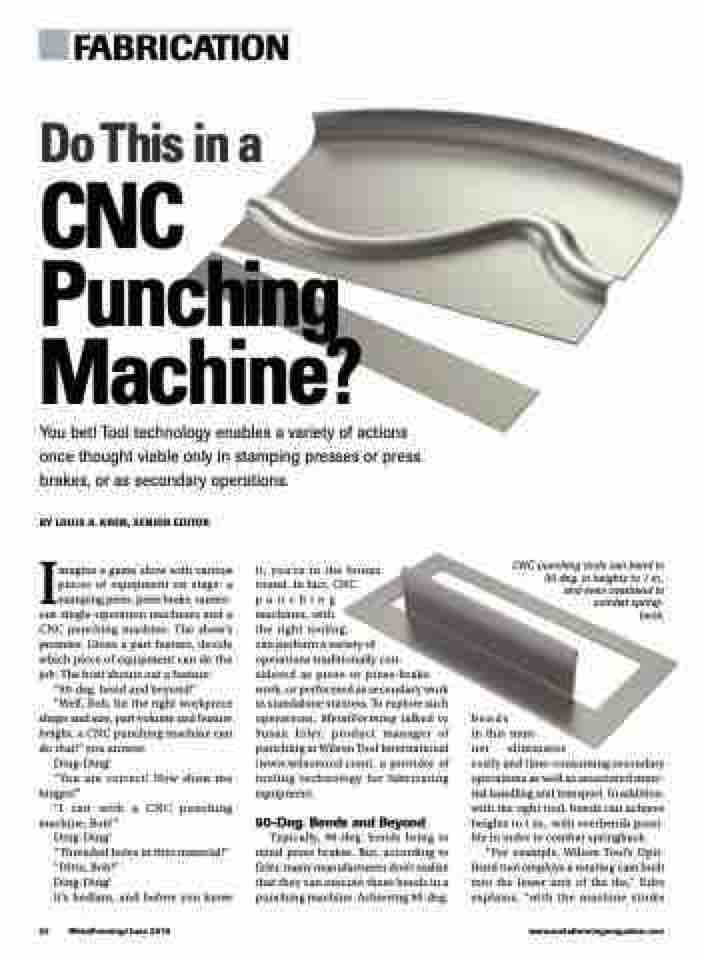

CNC punching tools can bend to 90 deg. in heights to 1 in., and even overbend to combat spring- back.

bends

in this man-

ner eliminates

costly and time-consuming secondary operations as well as associated mate- rial handling and transport. In addition, with the right tool, bends can achieve heights to 1 in., with overbends possi- ble in order to combat springback.

“For example, Wilson Tool’s Opti- Bend tool employs a rotating cam built into the lower unit of the die,” Erler explains, “with the machine stroke

24

MetalForming/June 2019

www.metalformingmagazine.com