Page 23 - MetalForming June 2019

P. 23

AMADA AMERICA, INC.

180 Amada Court • Schaumburg, IL 60173 www.amada.com/america

877-262-3287

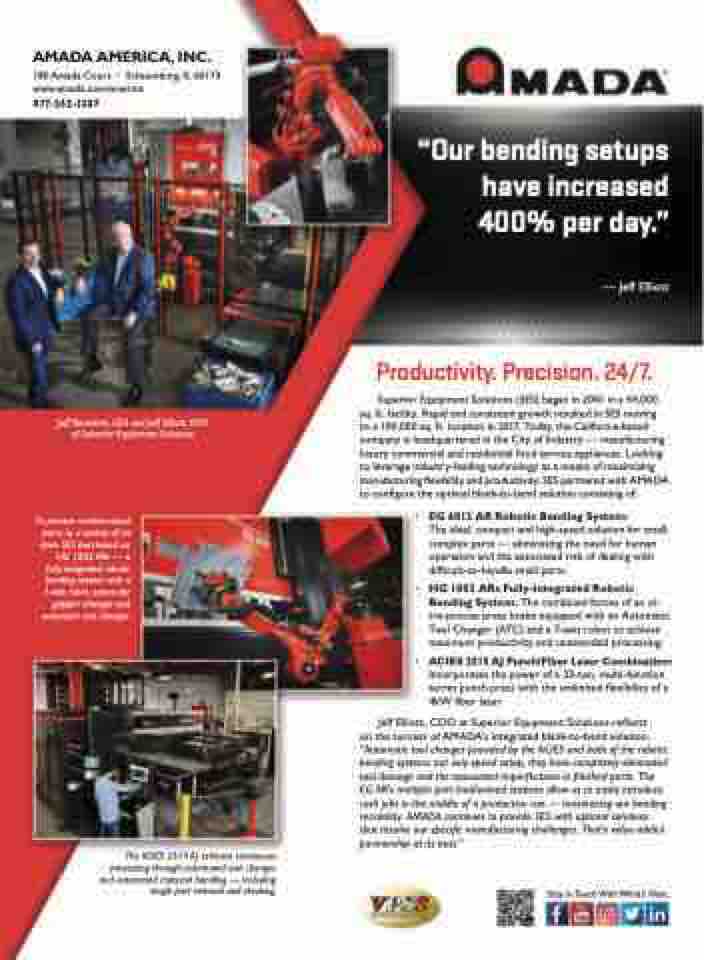

���� ���������� ��� ��� ���� �������� ��� of Superior Equipment Solutions

�� ������� ������������ parts in a variety of lot sizes SES purchased an ����������� ���������������� ������� bending system with a ������ ������ ��������� gripper changer and ��������� ���� ��������

“Our bending setups have increased 400% per day.”

— Jeff Elliott

Productivity. Precision. 24/7.

Superior Equipment Solutions (SES) began in 2001 in a 44,000 sq. ft. facility. Rapid and consistent growth resulted in SES moving to a 100,000 sq. ft. location in 2017. Today, the California-based company is headquartered in the City of Industry — manufacturing luxury commercial and residential food service appliances. Looking to leverage industry-leading technology as a means of maximizing ������������� ���������� ��� ������������� ��� ��������� ���� ����� �� �������� ��� ������� ������������� �������� ���������� ���

��� ����� ���� �� �������� ���������� processing through automated tool changes and automated material handling — including ������ ���� ������� ��� ���������

���� �������� ��� �� �������� ��������� ��������� �������

�� ��� ������� �� ������� ���������� ������������� ��������� “Automatic tool changes provided by the ACIES and both of the robotic bending systems not only speed setup, they have completely eliminated ���� ������ ��� ��� ���������� ������������� �� ������� ������ ��� EG AR’s multiple part load/unload stations allow us to easily introduce rush jobs in the middle of a production run — maximizing our bending ������������ ����� ��������� �� ������� ��� ���� ������� ��������� ���� ������� ��� ������� ������������� ����������� ������ ����������� ����������� �� ��� ������

���� �� ����� ���� ������ �����

•

•

•

EG 6013 AR Robotic Bending System:

The ideal, compact and high-speed solution for small, complex parts — eliminating the need for human operation and the associated risk of dealing with ������������������ ����� ������

HG 1003 ARs Fully-Integrated Robotic Bending System: The combined forces of an ul- tra-precise press brake equipped with an Automatic Tool Changer (ATC) and a 7-axis robot to achieve maximum productivity and unattended processing.

ACIES 2515 AJ Punch/Fiber Laser Combination:

Incorporates the power of a 33-ton, multi-function ������ ����� ����� ���� ��� ��������� ���������� �� � ��� ���� ������