Page 24 - MetalForming May 2019

P. 24

FABRICATION

Automating Flow via Robots

With more than 3000 system installs throughout North America, robotic integrator Acieta knows a thing or two about automating the movement of materials and fabricated parts. Here they pass along examples of how automation

has helped manufacturers streamline operations.

Virtually all fabricators share the same goals when it comes to automation: reduce costs, improve efficiency, offset the labor shortage, and improve safety and ergonomics. How fabricators get there varies, though integrated robotic solu- tions offer clear paths forward for large and small companies alike. The prime objective is addressing a range of fac-

BY JOE JANCSURAK, ASSOCIATE EDITOR

tors: floor space, throughput, flow, part size, volume, takt time and more.

By addressing these factors early on when working with a robotic integrator, fabricators reap the benefits of systems customized to meet their individual needs, explains Chris Poole, segment manager-fabrication for Acieta, head- quartered in Waukesha, WI, and Coun- cil Bluffs, IA. “My advice to fabricators,”

he says: “Look around your business, and if you see any operations that would benefit from robotic tending, know that cost-effective solutions exist.”

As the first company outside of Gen- eral Motors to integrate Fanuc robotic arms 36 years ago, Acieta’s fabrication business is driven by custom robotic part-handling installations for small-

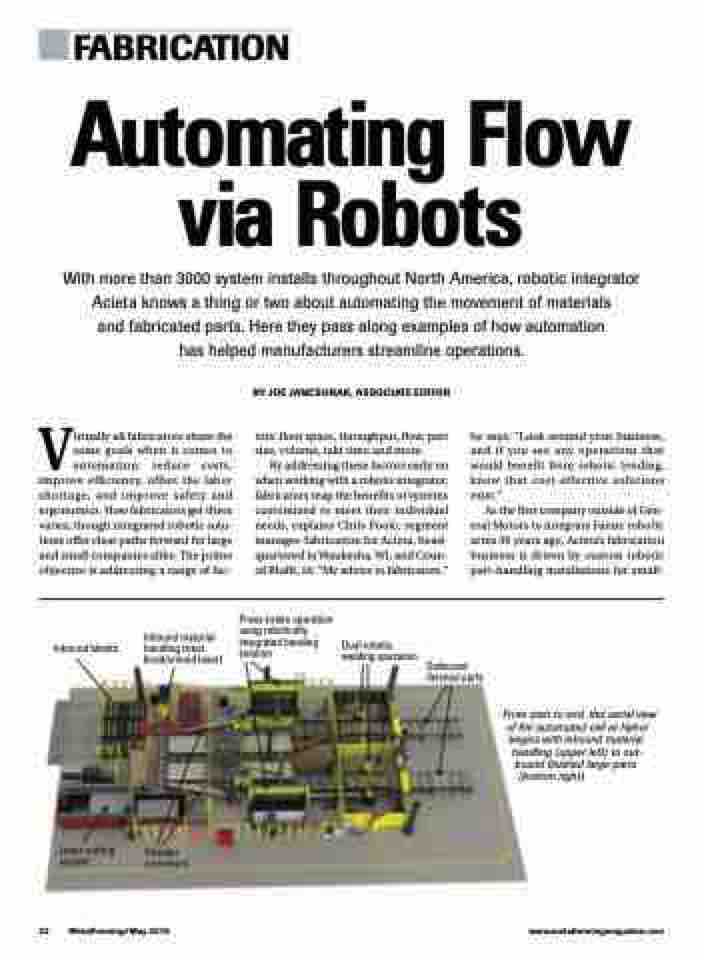

Inbound blanks

Inbound material- handling robot (load/unload laser)

Press-brake operation using robotically integrated bending solution

Dual robotic welding operation

Outbound finished parts

From start to end, this aerial view of the automated cell at Hytrol

begins with inbound material handling (upper left) to out- bound finished large parts

(bottom right).

22

MetalForming/May 2019

www.metalformingmagazine.com

Laser-cutting system

Transfer conveyors