Peter Ulintz

Peter UlintzNon-Traditional Forming of Aluminum Alloys

July 1, 2014Comments

While stampers can form aluminum alloys into complex shapes using traditional dies and pressroom equipment, the degree of complexity is limited by the material formability at room temperature, and forming speed. In some cases, to overcome these limitations metalformers opt for nontraditional processes, such as stretch forming, superplastic forming, hot or warm forming and high-energy-rate explosive forming.

Stretch Forming

/td> /td>

|

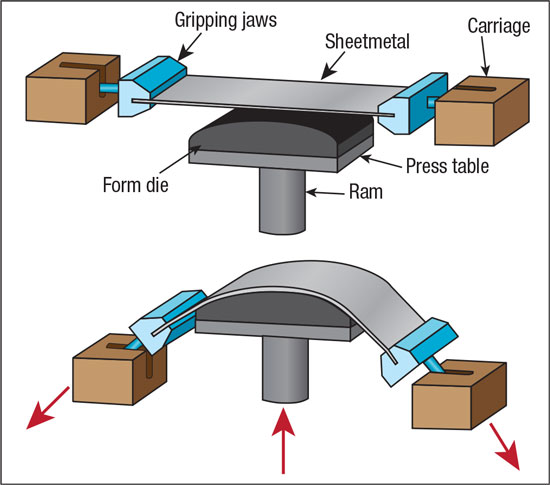

| Fig. 1—Stretch forming process steps |

Stretch forming simultaneously stretches and bends a piece of sheetmetal to form a large contoured shape. Auto manufacturers use the process to produce outer-body panels; aircraft manufacturers stretch-form fuselage skin sections. Benefits of the process include a lack surface marring, distortions and ripples, and accurate alignment of complex profiles.

Stretch forming occurs in a stretch press, with the sheetmetal securely held along its edges by gripping jaws. The gripping jaws, attached to a carriage, are pulled by pneumatic or hydraulic force to stretch the sheet (Fig. 1). The tooling used —a stretch-form block—comprises a solid contoured piece against which the sheetmetal is pressed. As the form die drives into the sheet, tensile forces increase until the sheet plastically deforms into its new shape.

Stampers select from two basic types of stretch-forming equipment: longitudinal and transverse. Longitudinal equipment stretches the workpiece along its length; transverse equipment stretches the workpiece along its width. Stretch presses are designed to be accurate and efficient, while CNC controls help provide part-to-part repeatability.

Superplastic Forming

Superplastic forming (SPF) takes advantage of the fact that some alloys can be slowly stretched at elevated temperatures well beyond their normal limitations. The process occurs at high temperature and under controlled strain rate to provide a tenfold increase in elongation compared to conventional room-temperature processes.

The process begins by placing the sheetmetal in an appropriate SPF die representative of the final part shape. Once the sheet and tooling are heated, gas pressure plastically deforms the sheet into the shape of the die cavity. The pressure profiles must be closely controlled during the process, since alloys of interest exhibit SPF behavior only within specific temperature ranges and strain rates.

SPF processes can produce parts deemed impossible to form using conventional techniques, but only with very specific alloys having the required fine-grained microstructure and strain-rate sensitivity (m-value).

Warm Forming

Some studies show a significant increase in formability of 5XXX- and 6XXX-series aluminum alloys during warm forming (T. Altan, G. Daehn, Ohio State University). Warm forming offers the ability to form complex sheet products that cannot be manufactured at room temperature, but at a lower cost than with SPF.

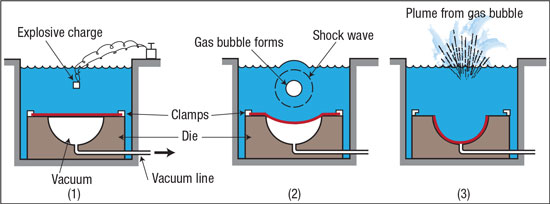

|

| Fig. 2—Explosive forming sequence |

During warm forming, the aluminum blank—and sometimes the die—is heated to 200 to 300 C before stamping. Processes using a heated die require increased tooling complexity and insulation to accommodate the electrical heating rods in the dies and/or blankholder. Cycle times are typically longer than traditional stamping processes due to the heating cycle.

Although the tooling and processing costs for warm forming are higher compared to conventional tooling, there are applications in which this technology can be very cost effective. Due to the complexity of the process and an overall lack of knowledge, further development work is required to establish robust design guidelines for warm forming.

Explosive Forming

Explosive forming is a high-energy-rate method used primarily to produce aluminum-alloy parts for aerospace applications. The process proves useful for parts that exceed the size limits of conventional stamping equipment, or when forming pressures are unobtainable with conventional methods due to alloy strength and/or sheet thickness.

Unlike SPF, explosive forming can be used with any aluminum alloy, with AA1100-O recognized as the most formable alloy (ASM Specialty Handbook: Aluminum and Aluminum Alloys).

Dies for explosive forming typically are of cast iron and cast steel. The process requires only a die cavity, as the underwater shock wave generated during explosive forming acts as the punch (Fig. 2). Prior to detonation, the air between the sheetmetal and die cavity may be evacuated, since forming speed is so great that any trapped air can prevent the workpiece from reaching the targeted die surface.

Deformation velocities can exceed 100 m/sec., compared to approximately 6 m/sec. for a conventional stamping process. The high pressure levels in explosive forming can substantially increase the yield and tensile strength of the workpiece when critical forming velocities are exceeded.

High-energy and high-velocity forming of aluminum alloys are not exclusively limited to explosive forming. Other methods, such as electrohydraulic and electromagnetic forming, also find use in limited applications (G. Daehn, Ohio State University). MFView Glossary of Metalforming Terms