Lot Traceability

October 1, 2015Comments

Lot traceability has been gaining in popularity as more government and regulatory bodies mandate traceability throughout the supply chain, across all industries. For North American manufacturers, regulatory bodies in Canada and the United States recently have launched huge initiatives to address increasing product recalls. These initiatives aim to make businesses more accountable for product traceability throughout the supply chain. Lot traceability also is a core component for many businesses in achieving ISO, TS and FDA compliance.

Lot traceability effectively means that a manufacturer knows which lots of product were used in which finished goods, and who received those finished goods. A key component in many ERP systems, lot traceability provides companies with a way to track problem products from their customer all the way back to the suppliers who provided materials and processes in between.

Lot traceability effectively means that a manufacturer knows which lots of product were used in which finished goods, and who received those finished goods. A key component in many ERP systems, lot traceability provides companies with a way to track problem products from their customer all the way back to the suppliers who provided materials and processes in between.

An important aspect of lot traceability is to keep track of which supplier’s materials were received to help ensure that, in the event of a recall, raw materials can be traced back to the appropriate supplier (if they were at fault) and to ensure that you know of any other operations applied to that raw material.

For metalforming companies, traceability back to the incoming raw material (sheets, coils, etc.) is a prime concern. Potentially large and costly problems lurk, however, because of the methods used by metalformers to identify material lots. Informal polling I have taken at PMA seminars indicates that many companies still trace products back to the material heat number provided by the mill. This practice can cause problems, since a heat (or batch) is the equivalent to one ladle of liquid metal. For steel produced by an integrated mill, this can be as much as 300 tons of steel.

Let’s assume XYZ Metalforming produces a high-volume stamped part weighing 0.5 lb. A potential problem with the raw material arises with its customer, and XYZ Metalforming must identify the potential number of problem parts in the field.

XYZ’s lot-control methods reveal that the suspect parts were produced from steel heat number XX-123. Further investigation reveals that the mill produced 266 tons of steel from that heat, the equivalent of more than one million parts. XYZ management, astonished at the large quantity of suspect products, might find the company on the brink of financial disaster.

What if XYZ had tracked its raw-material lots by master coil number rather than heat number? If we assume each master coil weighed 40,000 lb., we reduce the number of at-risk parts to 80,000—a vast improvement compared to one-million parts, but the suspect lot size is still considerably large, especially if XYZ is financially responsible not only for the defective parts it supplied but also for the cost of the assembly or subassembly in which the parts were used.

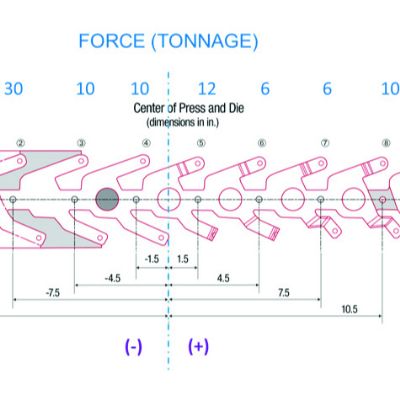

The best option: Restrict the material lot size to the exact coil used to produce the suspect parts. Assuming the service center slits each master coil into eight individually identified pup coils to the width that XYZ requires for its progressive die, and that each pup coil weighs approximately 5000 lb., each material now only results in 10,000 parts.

The message here is to work with your material-service center on a methodology that consistently identifies each individual coil and where it was slit from the master coil. For example, you and your service center may agree to identify individual coils by their master coil number, plus an individual coil designation indicating where each coil came from relative to the slitting line. Moving left to right, slit coils would be identified a, b, c, etc. , and the coil number for the first slit coil coming from the left-hand side of the master coil would be identified XX-123-a.

This approach, or one similar, also will prove invaluable for problem-solving and for conducting root-cause analysis. You may discover, for example, that a quality problem was restricted to one individual coil from the outside edge of one damaged master coil. Or you may learn that the problem persists with the coils slit from each of the outer edges of mater coil due to a condition called feathering—a thickness decrease due to coil crown.

Effective, efficient lot traceability relies on an accurate system to achieve desired quality control, inventory management, reduced costs and a stress-free business environment. ERP-based lot-tracking software eliminates expensive manual product tracking by providing a quick, precise and cost-effective operating system. This not only improves internal and external communication and efficient handling of product-quality spills, but also enables compliance with consumer-protection laws and regulations. MF

Peter Ulintz and Stuart Keeler will speak at PMA’s Higher Strength Steel seminar on October 27-28 in Cleveland, OH.Technologies: Tooling