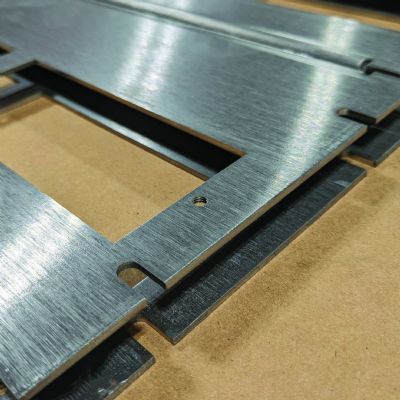

Everything a Sheetmetal Fabricator Needs to Know about Punch Press Tooling

September 1, 2011Comments

…lies within this comprehensive 72-page technical-solutions guide published recently by Mate Precision Tooling, Anoka, MN. Included are techniques and recommended procedures for setting die clearance, calculating punching force and performing punch and die maintenance. Readers also will learn how to punch small-diameter or narrow holes without experiencing machine or tooling complications.

…lies within this comprehensive 72-page technical-solutions guide published recently by Mate Precision Tooling, Anoka, MN. Included are techniques and recommended procedures for setting die clearance, calculating punching force and performing punch and die maintenance. Readers also will learn how to punch small-diameter or narrow holes without experiencing machine or tooling complications.

Included is a nine-page Tips & Techniques chapter that informs fabricators on forming of raised beads, using stroke control to achieve consistent form height, shaving to make straight-walled holes without drilling and how to establish a draft angle when forming tabs to eliminate binding, among numerous other applications. And, a two-page Troubleshooting Quick Reference Guide provides possible causes and suggests solutions for excessive burrs, poor hole quality, punch galling, rapid tool wear and workpiece marking, among other problems.

Mate Precision Tooling: 763/421-0230; www.mate.comView Glossary of Metalforming Terms

See also: Mate Precision Tooling

Technologies: CNC Punching