Say So Long to Sheet Skeletons

January 1, 2011Comments

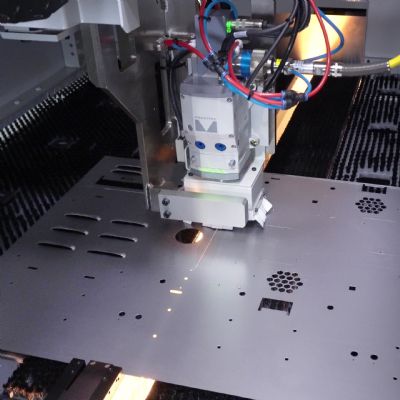

Trumpf Inc., Farmington, CT, introduced its new solution for dealing with messy sheet skeletons coming off of CNC punch presses: skeleton-free processing, a feature available on its TruPunch 3000 press. This innovation relies on common split cuts; however, extensive programming no longer is required to make them. Any possible geometric configuration already is programmed into the machine software, enabling the sheet layout to be optimized and prepared for the necessary release strokes.

Parts are initially processed in sequence and then freely punched prior to discharge or removal. Then, a separating tool with a bilevel stripper rotates the parts or scrap as needed to facilitate discharge via the chute, and remaining strips are completely shredded.

Trumpf officials say that the feature will increase material utilization by an average of 10 percent, and also conserve energy—peripheral equipment for cutting and disposing of scrap no longer are necessary.

Trumpf Inc.: 860/255-6000; www.us.trumpf.com

Industry-Related Terms: Scrap, Stripper, Strips, CNC, Material Utilization

View Glossary of Metalforming Terms

View Glossary of Metalforming Terms

See also: TRUMPF Inc.

Technologies: CNC Punching

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. CNC Punching

CNC PunchingCNC Punching: Positive Stop a Positive Advantage

Lou Kren Monday, February 27, 2023