Marking Tools for CNC Punch Presses

April 1, 2010Comments

Mate Precision Tooling, Anoka, MN, introduces a quick and reliable method for marking fabricated parts in five different s during CNC punching: the EasyMark 5-In-1 Tooling Kit.

The thick-turret application tooling, for machines without a bottom-stroke forming feature, can be set up to automatically perform any of the following five marking operations:

• Write numbers, dates and other identifying information on a part surface using a special marker. No penetration or material removal is required, the marker does not dry out for two weeks or more and the marked information is erasable if desired.

• Etch the sheetmetal surface with permanent marking information using one of two (120- and 150-deg.) supplied diamond inserts.

• Cut or scribe the protective film on sheetmetal surfaces using a supplied brass insert to expose localized areas on the part without damaging underlying material.

• Create cone-shaped indentations (centerpoint down) on the part surface to locate the part with other components for later assembly.

• Perform high-speed dot-matrix marking in this mode using a supplied carbide insert.

The EasyMark kit contains all components and tools for all five marking modes, including special A-Station guide and canister, marker pen, one brass, one carbide and two diamond inserts, three types of springs for the diamond and brass inserts, roller ball and blank dies.

Mate Precision Tooling: 763/421-0230; www.mate.com

View Glossary of Metalforming Terms

See also: Mate Precision Tooling

Technologies: CNC Punching

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. CNC Punching

CNC PunchingMurata Machinery USA Celebrates 50 Years of Automation in No...

Friday, February 23, 2024

CNC Punching

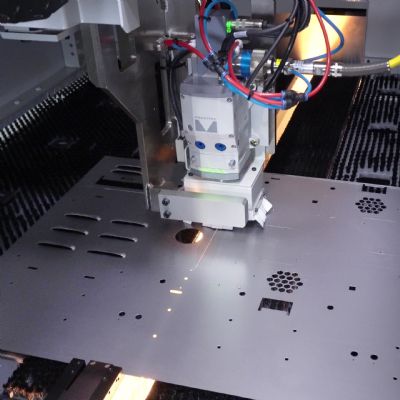

CNC PunchingMultifunction Fiber Laser Turret Punch Press

Tuesday, June 20, 2023

CNC Punching

CNC PunchingCNC Punching: Positive Stop a Positive Advantage

Lou Kren Monday, February 27, 2023