Eye-Injury PreventionEasy and Affordable

July 1, 2008Comments

Eye injuries, which occur at an estimated rate of 1000/day in U.S. businesses, take a great personal toll on American workers. Add up the lost production time, medical expenses and workers’ compensation claims, and the estimated cost of these injuries reaches $300 million/yr.

Yet, companies can prevent some 90 percent of eye injuries through the proper use of protective eye wear and by investing to create and implement an eye and face safety program. Protective eye and face equipment is inexpensive—a good pair of safety glasses or goggles costs less than $20—compared to the expenses related to eye injuries, bad publicity for the company and the negative impact on worker morale.

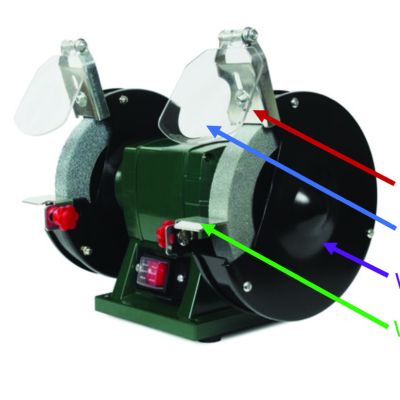

The goal of eye and face protection is to shield the eyes from injury. Most impacts to the face come from flying objects, usually particulates. If the particulate hits the eye, it causes direct damage that makes it difficult for the eye to repair itself. Almost 70 percent of eye accidents result from flying or falling objects, or from sparks striking the eye. Most of the objects are smaller than a pin head, and most travel faster than a hand-thrown object. (Contact with chemicals causes the remaining 30 percent of eye injuries.)

As with any safety program, the first step in establishing an eye- and face-protection program is to conduct a hazard assessment, which should list what personal-protective equipment (PPE) will be used to protect against the hazards. Hazards should be assessed by work activity, and the hazard assessment should determine the type of PPE required for each activity.

|

In addition, companies should prepare a written plan that specifies how the PPE will be selected, the worker training required to ensure proper use of the PPE, and how prompt emergency care will be provided in the event of an accident.

OSHA has an excellent Eye and Face Protection eTool on its website (osha.gov/SLTC/etools/eyeandface/ppe/ selection.html) that can assist managers in preparing a hazard assessment. It also provides information on selecting PPE, and summarizes OSHA requirements.

Webinar

Webinar