Constructing a Visible Supply Chain

June 1, 2008Comments

The following article is summarized from a white paper, The Visible Supply Chain—Ensuring End-to-End Optimization, created by Ventana Research, San Mateo, CA, and sponsored by Epicor Software Corp., Irvine, CA.

Today’s supply-chain managers need a supply chain that is visible, allowing them to know the location and status of all physical components, from raw materials to finished goods, as they move from suppliers through the stages of production to delivery to customers.

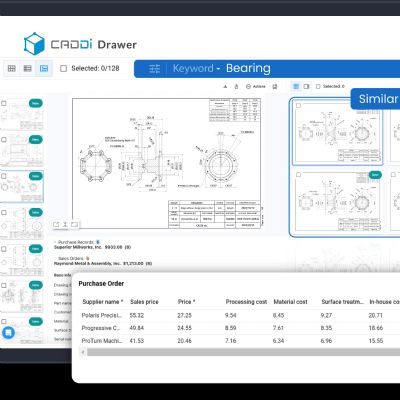

Most supply-chain information is managed in a combination of a company enterprise-resource-planning (ERP) system and specialized software for supply-chain management. To make these technologies work in a visible supply-chain environment, key technologies must be added to the mix: dashboards and other tools that can track materials and product flow in the supply chain, and information access and business-intelligence tools for analysis.

Modern dashboard technology applied to a visible supply chain gives production and distribution resource managers the ability to see numerically and graphically what is happening in their areas. A dashboard is a collection of different reports, all in one page or view, that contains high-level summary information rather than detail transactions. In a properly visible environment, managers, via dashboards, can see their own data as well as data from other processes that affect their work. In either case, dashboard users can drill down to find the root causes of the behavior of monitored resources.