DM 4140 Powder Added to Binder Jetting Process—Ideal for High-Load Applications

February 4, 2022Comments

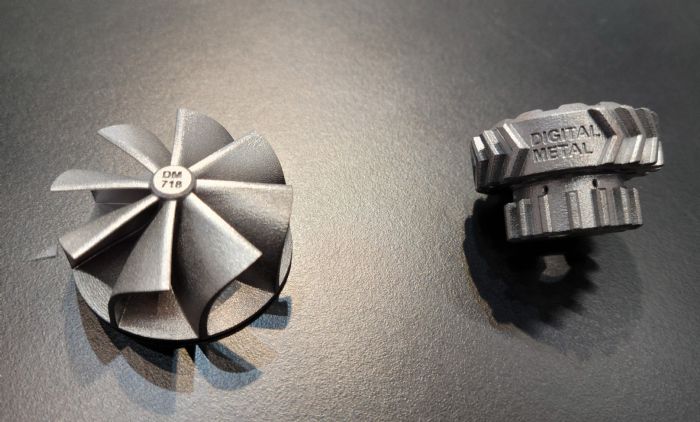

At Formnext...Digital Metal AB showcased numerous detailed parts produced via a binder-jetting process developed by Höganäs. This technology enables the production of highly complex objects with superior surface finish and repeatable accuracy, according to Alexander Sakratidis, the company’s sales and marketing manager, who detailed for 3DMP the process and parts it produces. Besides developing, manufacturing and selling printers, the company also offers small-volume or mass-production printing services, and recently has expanded its efforts in North America.

At Formnext...Digital Metal AB showcased numerous detailed parts produced via a binder-jetting process developed by Höganäs. This technology enables the production of highly complex objects with superior surface finish and repeatable accuracy, according to Alexander Sakratidis, the company’s sales and marketing manager, who detailed for 3DMP the process and parts it produces. Besides developing, manufacturing and selling printers, the company also offers small-volume or mass-production printing services, and recently has expanded its efforts in North America.

At the show, Digital Metal announced that it has added low-alloy DM 4140 steel powder to its binder jetting system, ideal for components exposed to high loads.

In collaboration with Hyundai Motors, Digital Metal developed and certified DM 4140 in order to manufacture gearbox control fingers using binder jetting. DM 4140 is ideal for high-load components in automotive, consumer goods and industrial applications. The material is printed with an ink commonly used for other steel and nickel-based alloys, although, as company officials note, the process has been modified and optimized to reach properties consistent with metal injection molding standards. By alternatively applying quenching and subsequent tempering treatment in an as-sintered state, tensile properties may be tuned toward application requirements.

See also: Digital Metal AB

Technologies:

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Pressroom Automation

Pressroom AutomationRemote, Web-Based Robot Control and Error Recovery

Monday, May 13, 2024

Management

ManagementAMT: March Manufacturing-Technology Orders Show Typical Spik...

Monday, May 13, 2024

Tooling

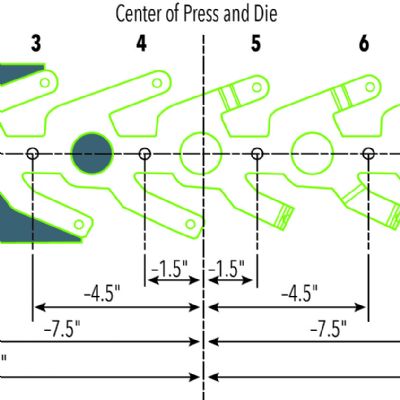

ToolingManaging Off-Center Press Loads—What Every Press Technician ...

Peter Ulintz Monday, May 13, 2024