Answering these questions, and assessing performance by revisiting these questions, helps develop the all-important definition of success that drives ERP decisions.

ERP Powered by AI

News from ERP providers reference artificial intelligence (AI), so let’s take a closer look at what that means.

Not just a number cruncher, AI “can be a creative spark, generating new ideas and concepts beyond the limitations of human thought,” offers a Forbes article, “5 Ways Leaders Can Win Hearts And Minds, And Drive Results—With AI.” Consider “AI-powered brainstorming tools,” the article continues, “that suggest unconventional solutions, or algorithms that identify unexpected connections between seemingly unrelated data points. This can lead to groundbreaking innovations that human minds might have missed.”

AI in ERP systems also “expands analytics capabilities, easing the ability to gather and analyze data across different business functions, according to “ERP And SCM—What To Expect In 2024,” another Forbes article. “Doing so provides insights into performance, demand forecasting, customer behaviors, inefficiencies, and financial and risk factors. Such advanced analytics integrated into ERP systems help users make informed decisions and prepare their businesses for future challenges.”

The Latest from ERP Providers

Heady stuff, for sure. Read on for recent news from some ERP providers. And, in MetalForming’s June/July 2024 issue, we’ll see, via case studies, how metal formers and fabricators are leveraging the power of ERP to gain success in the marketplace.

Cetec ERP Launches AI Chatbot

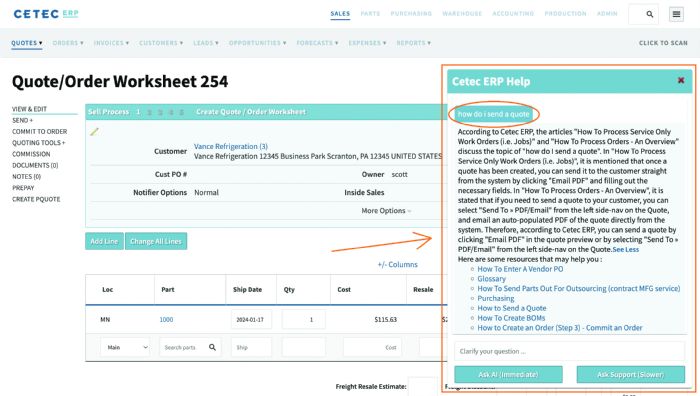

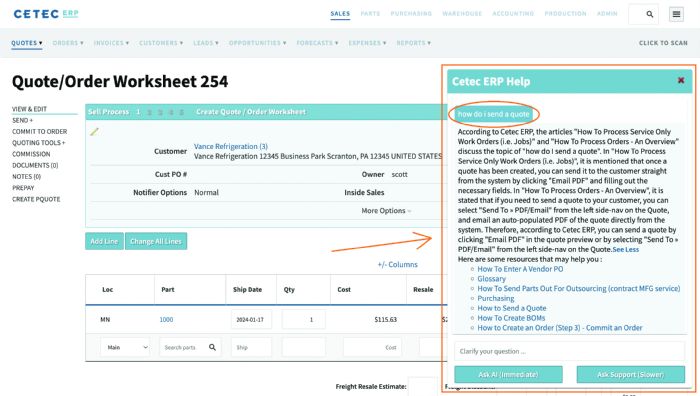

ERP-software provider Cetec ERP, Austin, TX, has launched a new AI-based chatbot tool, developed to provide users with immediate responses to the most common questions. Once users ask a question—from any screen within Cetec ERP—the AI chatbot reads and summarizes Cetec ERP’s website and documentation to provide an answer. It also provides links to relevant document pages, including how-to videos. If questions require further assistance, customers with a support plan can create a ticket with the Cetec support team for more personalized, in-depth help.

ERP-software provider Cetec ERP, Austin, TX, has launched a new AI-based chatbot tool, developed to provide users with immediate responses to the most common questions. Once users ask a question—from any screen within Cetec ERP—the AI chatbot reads and summarizes Cetec ERP’s website and documentation to provide an answer. It also provides links to relevant document pages, including how-to videos. If questions require further assistance, customers with a support plan can create a ticket with the Cetec support team for more personalized, in-depth help.

The AI chatbot promises to provide immediate assistance, fast-track support tickets, and become a useful and timesaving tool for any manufacturing company using Cetec ERP, including job shops and medical-device manufacturers.

Rootstock Debuts AI Solution for its Manufacturing Cloud-ERP System

At its recently held Rooted-In Manufacturing Conference, Rootstock Software introduced AIRS (AI from RootStock), a new AI solution for the company’s manufacturing cloud-ERP system. Built on the Salesforce Einstein 1 platform, AIRS leverages Rootstock’s ERP dataset, including order, supply, financial and production data collected from CRM, SCM, PLM, IoT platforms and other systems to create a complete signal-chain decisioning platform. The platform, say company officials, bridges the physical and digital worlds and enables smart, autonomous manufacturing-related decision making using predictive and generative AI.

Reported advantages:

- Improved material requirements planning, as manufacturers can predict lead times, foresee production bottlenecks, dynamically allocate materials and resources, and reduce waste.

- Improved forecasting accuracy, as manufacturers can predict sales trends and new opportunities.

- Improved supplier collaboration and risk management, by predicting spending and supplier trends.

- Deeper insight into financials and cash-flow forecasting, leading to more accurate financial planning.

- Enhanced communication, as, using Salesforce Prompt Builder, AIRS can streamline the creation of dunning letters and enable personalized, scalable customer interactions that integrate with Rootstock’s RootForms.

“AIRS represents a significant step toward building agile manufacturing that can withstand continued volatility and disruptions,” says Raj Badarinath, Rootstock chief product and marketing officer. “With AIRS providing predictive insights, manufacturers can foresee risks and opportunities across their organization. And, in response to continually incoming signals, AIRS can recalculate projections and enable dynamic adjustments to order-to-cash, procure-to-pay and plan-to-produce processes.”

Availability of AIRS will be announced soon.

New Integration in JobBoss2 ERP Software Delivers Advanced Quality Management

ECI Software Solutions announced that its job-shop product, JobBoss2, now integrates uniPoint quality-management software to deliver advanced quality management and enhanced customer service, according to company officials. The new solution, JobBoss2 Advanced Quality, reportedly alleviates job-shop challenges such as improving consistent quality, which requires balancing diverse customer requirements, and managing complex production schedules and fluctuating material availabilities. Features in the paperless new product include a complete ISO-compliance solution that bridges a multitude of quality standards; 23 quality-management modules; more than 100 quality reports; 800 quality metrics; and 80 trend-analysis graphs. In addition, a built-in quality workflow system, or to-do list, ensures that no quality task falls through the cracks, and users can track the total administrative cost of quality at every stage.

Reports can be exported through Microsoft Office, email or PDF. The integration with critical JobBoss2 ERP data reportedly eliminates redundant data entry and provides businesses with a historical audit trail.

Epicor Surpasses $1 Billion in Annual Recurring Revenue, Eyes AI-Powered ERP

Epicor announced it has surpassed $1 billion in annual recurring revenue, achieved via the company’s focus in driving adoption of its subscription-based industry ERP-cloud portfolio. In its FY 2023, Epicor realized 42% year-over-year growth in software-as-a-service (SaaS)-based cloud revenue, with 70% of new customers adopting a subscription-based offering. And, since 2018, “we’ve invested approximately $1 billion in cloud-based innovations to advance our product offerings with the purpose-built, scalable and secure technologies that our customers require,” says CEO Steve Murphy.

Investment moving forward centers on AI, according to Joe Ayers, Epicor CFO, with a vision that the company calls cognitive ERP. This symbiosis between AI and ERP reportedly aims to redefine processes and operations across supply-chain industries, adapting the technology to the worker in their contextual environment or workflow, thus reducing the complexity and friction in how users have traditionally interacted with and extracted intelligence from their enterprise technologies.

During its Epicor Insights 2024 customer conference in late May, the company will detail its cognitive ERP strategy, designed to help users leverage AI to drive significant enhancements in decision-making, forecasting, customer service and overall operational efficiency. Also at Epicor Insights: unveiling of an integrated portfolio of new AI and data-platform capabilities.

New Acumatica ERP Release Features Improved Material-Demand Planning, Optimized MRP Generation and More

March welcomed Acumatica 2024 R1, the latest Acumatica semi-annual ERP software release, designed to increase product usability, and enhance user productivity and efficiency.

|

Mark your calendar for August 13-14, 2024, as MetalForming magazine and the Precision Metalforming Association host an informative forum on Industry 4.0 applications for metal formers and fabricators, and a tour of some of the industry’s leading ERP software systems. Industry 4.0 Forum and ERP Shootout, an in-person event held at PMA headquarters in Independence, OH, features Industry 4.0 presentations on day one as well as a networking reception. Day two features sessions that provide in-depth software demonstrations from four leading ERP suppliers: Plex, by Rockwell Automation; Epicor Software; ECI Software Solutions; and DelmiaWorks. Users will participate in lively group discussions designed to address any questions regarding software features and functionality. More details and to register.

|

The company offers ERP editions tailored to various industries. The Manufacturing Industry Edition addresses the industry’s unique needs, as manufacturers continue to face a stubbornly unstable economy, a still-chaotic supply chain, ongoing labor shortages and a growing need to modernize facilities, offer Acumatica officials. The lates release addresses these challenges, with benefits such as:

- Improved material demand planning by forecasting optional stock and non-stock kit components

- Flexibility for manufacturing workers to report production operations when they run in parallel

- Optimized MRP generation with ‘planning horizons’ that enable organizations to define time-constrained data for inclusion in supply and demand calculations

- Configured MRP and distribution-requirements planning (DRP) to include or exclude sales-order types and improve planning by excluding returns and other types of orders from inventory-planning calculations.

StartProto Achieves ITAR Registration, Partners with Consultant Firm

StartProto, provider of cloud-based manufacturing software, announced its recent achievement of International Traffic in Arms Regulations (ITAR) registration. This registration solidifies its commitment to adhering to rigorous compliance standards and fortifies its position as a trusted partner for US-based manufacturing companies, offer company officials.

ITAR registration is a crucial step for StartProto, they explain, showcasing the company’s dedication to upholding the stringent regulations governing the export and import of defense-related articles and services. With this certification, the firm demonstrates its capability to handle sensitive and controlled technical data securely within its cloud manufacturing-software platform.

Also, StartProto announced a partnership with Pennybacker Service, a boutique professional services and consulting firm that helps manufacturing business owners and entrepreneurs implement turnkey solutions to automate operations. The partnership is expected to help expand its customer base with government agencies, contractors and manufacturers.

“We look forward to collaborating with Pennybacker Services to support their growing customer base in streamlining their businesses,” says company CEO Tim Felbinger, adding that “our lightweight ERP solution fits a niche for smaller contractors within SAM.gov who need something easy to use.”

Robust Shop Floor Module, More in 2024 DelmiaWorks ERP Release

The release of DelmiaWorks 2024 manufacturing ERP system focuses on technology and customer ideation to improve users’ experiences and streamline day-to-day activities, according to company officials.

A key feature of the 2024 release, the Shop Floor Operator module, features dashboard cloning designed to simplify implementation and reduce setup time; new print-label workflow options designed to increase accuracy while reducing waste; and additional languages for minimizing language barriers on the manufacturing floor.

Also, the release includes RealTime process monitoring (RTPM) that enables operations to leverage real-time data collection to make decisions and course-correct production operations. RTPM highlights include Action Manager, enabling users to deploy common functions quickly across multiple devices and take advantage of new supported technology.

Other new or improved features in 2024 DelmiaWorks ERP:

- The new Stop Process feature in Assembly Track that prevents users from reporting the status for an unscheduled process or a process that is not 100% complete, eliminating production reporting errors.

- Improved audits, compliance and traceability through stronger data protection, document-control electronic sign-off and serial-number traceability.

- New Financial Summary and Detail Smart Page business-intelligence dashboards that offer drill-down capabilities allowing for comprehensive financial insights and analyses.

- An enhanced user experience, including efficient adjustment of scheduled days off for the shop calendar to match fluctuating machine and labor-resource availability; easier projection of material shortages using the bill of materials Tree Explosion feature with a redesigned user interface; and improved material repair and overhaul work-order labor-management experience via the ability to assign an entire work order to maintenance- and tooling-team members

Global Shop Solutions Stresses Stability, Highlights Cloud ERP Advantages

Pointing out the importance of stability in a software provider, Global Shop Solutions recently recognized Chris Pinaire, the company’s director of new implementations, for his 20 yr. of service to the manufacturing industry. After several years as a senior consultant, Pinaire was elevated to his current position where he works to continuously improve the manufacturing processes of users via the company’s cloud ERP systems. Cloud ERP from Global Shop Solutions resides on cloud-based servers provided by Amazon Web Services. Users can expect quick and secure data access, including accurate, real-time data, according to company officials, as well as automated and continuous backups, rapid system response, and semi-annual upgrades tailored to users’ needs. ERP maintenance provided by Global Shop Solutions delivers a guaranteed uptime of 99.95%. Users, requiring less IT time and costs, receive an ERP solution integrated with CAD and shop equipment, and easily can fulfill compliance requirements.

The company also provide on-premise ERP software.

New Plex Report Highlights Smart-Manufacturing Investment as Key to Meeting Current and Future Challenges

Plex, by Rockwell Automation, a provider of ERP solutions for manufacturing, offers its newly released 2024 State of Smart Manufacturing Report, detailing current and future challenges and opportunities obtained through surveys of more than 1500 manufacturers. The report covers the expanding use of generative AI, the ongoing need for an adaptive workforce and more.

Key takeaways include current external obstacles to growth—inflation followed by rising energy costs. Third on the list: cybersecurity, a compelling indication of the increasingly close digital-physical infrastructure connection, note company officials. Manufacturers plan to mitigate inflation and rising energy costs by investing in new technology.

New in the 2024 report, AI and machine learning (ML) are seen as delivering bigger business outcomes than all other smart-manufacturing capabilities. Respondents believe that industry leaders are setting the pace by using data to fuel AI and ML, and optimize processes. However, those surveyed say that their own organizations effectively use only 44% of collected data.

Besides the constant challenge of workforce recruitment and retention, manufacturers also grapple with the longstanding issues of quality and efficiency. Improved quality is the number-one outcome respondents hope to achieve from existing smart-manufacturing technology, the report offers. Nearly half of respondents say that quality control tops the chart for planned AI and ML use in 2024, placing it ahead of cybersecurity, process optimization, supply-chain management and robotics.

Manufacturers, according to the report, say that workforce, quality, efficiency and sustainability challenges, along with the rapidly growing need for cybersecurity, are driving them to choose data-centered solutions. To that end, 83% of respondents report that the obstacles faced are accelerating digital transformation within their companies.

When manufacturers talk about the ways in which they are future-proofing their businesses in order to stay competitive, capitalizing on AI clearly is the primary goal, the report states. Their top-three investment areas over the next 12 months: generative or causal AI, collaborative robots, and autonomous mobile robots/automated guided vehicles.

Access the report.

ShopEdge ERP Tailored to Metal Stamping

ShopEdge Software, Inc. highlights how its modular ERP software is designed to coordinate metal stamping, and to enforce industry best practices, enabling strengthened business processes and realized long-term benefits. The software’s industry-specific design, officials explain, drives productivity and profitability improvements for users. Stated software features include a powerful scheduling engine, integrated tooling, inventory automation and EDI form integration. Business-intelligence and dashboard tools, derived from real-time data, enable improved, knowledgeable decisions.

Originally designed for shop-floor operations using Production Scheduling and Inventory Control modules, the full ERP software includes complete functionality to operate a metal stamping business. Innovations in capturing real-time production efficiencies and inventory data, combined with comprehensive business-intelligence tools, explain company officials, provide essential up-to-date information to give users precise knowledge of the states of their businesses.

An important newer feature, real-time shop-floor messaging, is designed for stampers interested in improving visibility, efficiencies and communication on the production floor. For example, operators can directly communicate with material handlers, be it for a need for raw materials, work in process, or a container drop-off or pick-up. Material handlers are notified immediately when a request is sent, and live dashboards alert users of waiting requests. Messages can be sent back and forth, as required. MF

See also: Global Shop Solutions, Epicor Software Corp., Plex, A Rockwell Automation Company, ShopEdge Software Inc., 3D Systems

Technologies: Management

Lou Kren

Lou Kren

ERP-software provider Cetec ERP, Austin, TX, has launched a new AI-based chatbot tool, developed to provide users with immediate responses to the most common questions. Once users ask a question—from any screen within Cetec ERP—the AI chatbot reads and summarizes Cetec ERP’s website and documentation to provide an answer. It also provides links to relevant document pages, including how-to videos. If questions require further assistance, customers with a support plan can create a ticket with the Cetec support team for more personalized, in-depth help.

ERP-software provider Cetec ERP, Austin, TX, has launched a new AI-based chatbot tool, developed to provide users with immediate responses to the most common questions. Once users ask a question—from any screen within Cetec ERP—the AI chatbot reads and summarizes Cetec ERP’s website and documentation to provide an answer. It also provides links to relevant document pages, including how-to videos. If questions require further assistance, customers with a support plan can create a ticket with the Cetec support team for more personalized, in-depth help.