Brad Kuvin

Brad KuvinIt's a Whole New World for Auto Suppliers

September 1, 2010Comments

Steel companies remain committed to expanding their research and development efforts to fulfill a promise to the automotive industry to bring new alloys to market with improved manufacturability (formability, weldability, etc.). That’s one of several key takeas gleaned from my recent interview with a handful of leading auto-steel representatives from the Steel Market Development Institute (SMDI). I caught up with SMDI execs during the Center for Automotive Research Management Briefing Seminars held August 2-5, 2010, in Traverse City, MI.

I’ll report fully on my conversations with SMDI’s top brass in a future issue of MetalForming. In the meantime, here are three additional takeas:

- Advanced high-strength steels not only are here to stay, but their use is predicted to triple over the next few years, according to OEMs surveyed by Ducker Worldwide. As reported during the meetings in Traverse City, this move is driven by the escalation of fuel-economy standards. Fuel efficiency of U.S. light vehicles must climb from 26.8 miles/gal. in 2008 to 35 miles/gal. by 2020; some OEMs have set goals well beyond that threshold, such as Hyundai’s CAFE goal of 50 miles/gal. by 2025. As a result, use of dual-phase steels in vehicles is expected to rise from 75 lb./vehicle in 2009 to 275 lb./vehicle in 2020. The biggest increase will come from dual-phase steels, but TRIP steels also will become a major player. Prepare your pressrooms accordingly.

- The move to hybrid and all-electric vehicles provides automotive OEMs a once-in-a-lifetime opportunity to approach vehicle design from a “Greenfield perspective,” not hampered by having to repurpose parts and assemblies from pre-existing programs. This presents a bevy of opportunities to metalformers to come to the table with unique solutions for manufacturing critical-load-path parts from alternative processes—rollforming and hydroforming for example. This could be a huge development that could result in a complete supply-chain makeover.

- And, along with the move to electric vehicles come OEM directives for a greener supply chain. Leading the pack is Ford, which recently asked 35 of its top global suppliers for energy-use and greenhouse-gas emissions data. Again, steel suppliers have stepped up in a big —data presented in Traverse City shows that U.S. steelmakers have reduced energy consumption per ton of steel shipped by 33 percent since 1990. Odds are that someday soon the greening of the supply chain will impact lower Tier suppliers. Do you know your company’s carbon footprint? Better get ready to answer that question!

(Should you be interested in learning how carbon footprint is measured, there are several online calculators, including one at www.carbonfootprint.com/corporate.html. The site supports small and medium-sized companies, as well as large corporations.)

View Glossary of Metalforming Terms

Technologies: Management, Materials

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Management

ManagementMetalForming LIVE 2024: Recruit, Retain, Train Reca...

Monday, January 22, 2024

Webinar

Webinar  Management

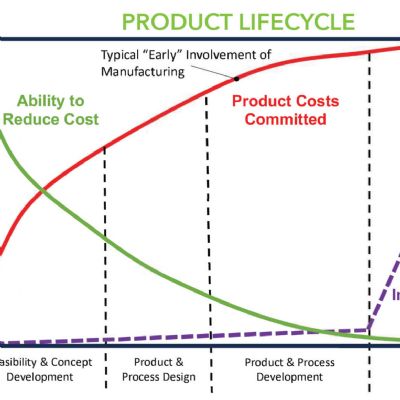

ManagementDesign for Manufacturing

Peter Ulintz Friday, October 27, 2023

Podcast

Podcast