All-Clad’s Robotic Blanking Cell and Greenerd Deep-Draw Hydraulic Press

January 3, 2013Comments

Cookware manufacturer All-Clad, Canonsburg, PA, recently upgraded its metalforming operations by installing a robotic blanking cell and deep-draw hydraulic press. Master blanks of three or five bonded layers of stainless steel and aluminum are straightened before a robot indexes them through a multi-station die. As a conveyor carries the blanks to a deburring cell, the robot moves the skeleton to a shear, which trims the edge. This operation removes a series of spot welds that help to hold the layers together. With the welds removed, the layers can be separated and scrapped.

At the Greenerd hydraulic press (562 tons of ram force, 280 tons of cushion force and 20 tons of ejection force), blanks are hand-fed through a lubrication system before being placed in the deep-draw tool. Shown is drawing a 7-qt. stock pot using a 7.75-in. draw that reduces a 20.75-in. blank to 17.75-in. dia.Industry-Related Terms: Stainless Steel, Blank, Blanking, Die, Draw, Drawing, Edge, Hydraulic Press, Ram

View Glossary of Metalforming Terms

View Glossary of Metalforming Terms

See also: Greenerd Press & Machine Co.

Technologies: Pressroom Automation, Stamping Presses

Comments

Must be logged in to post a comment. Sign in or Create an Account

There are no comments posted. Stamping Presses

Aaron Heinrich April 26, 2023

Motion-Control Technology Aids Precision Automotive Manufact...

Aaron Heinrich April 26, 2023

Stamping Presses

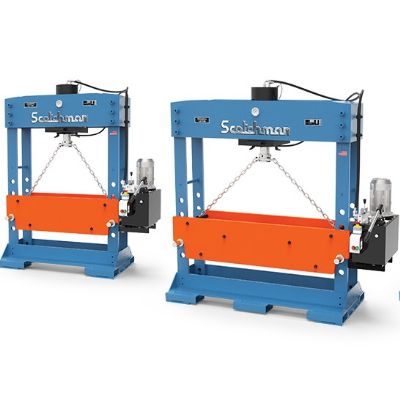

Stamping PressesH-Frame Hydraulic Presses Feature Table-Raising Capability

Monday, December 18, 2023

Stamping Presses

Stamping PressesDuring FABTECH 2023, MetalForming Magazine Catches ...

Monday, October 23, 2023

Video

Video