Page 28 - MetalForming January 2020

P. 28

FABRICATION

Five-Axis Laser

26

MetalForming/January 2020

www.metalformingmagazine.com

Simplifies Complex Part Production

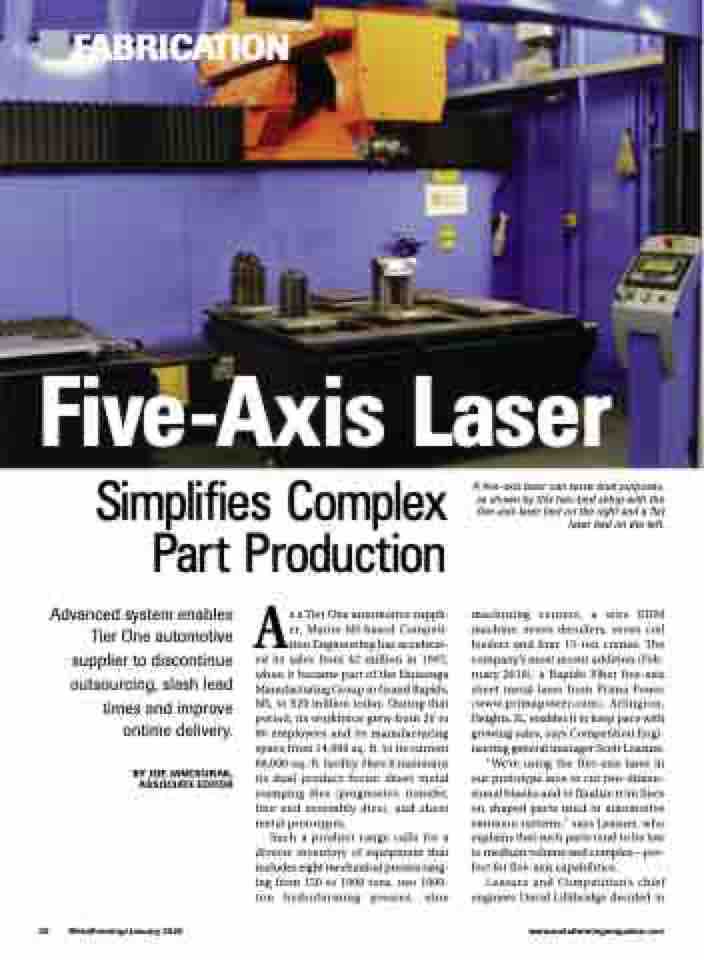

A five-axis laser can serve dual purposes, as shown by this two-bed setup with the five-axis laser bed on the right and a flat

laser bed on the left.

machining centers, a wire EDM machine, seven decoilers, seven coil feeders and four 15-ton cranes. The company’s most recent addition (Feb- ruary 2018), a Rapido Fiber five-axis sheet metal laser from Prima Power (www.primapower.com), Arlington, Heights, IL, enables it to keep pace with growing sales, says Competition Engi- neering general manager Scott Leasure.

“We’re using the five-axis laser in our prototype area to cut two-dimen- sional blanks and to finalize trim lines on shaped parts used in automotive emission systems,” says Leasure, who explains that such parts tend to be low to medium volume and complex—per- fect for five-axis capabilities.

Leasure and Competition’s chief engineer David Lillibridge decided to

Advanced system enables Tier One automotive supplier to discontinue outsourcing, slash lead times and improve ontime delivery.

BY JOE JANCSURAK, ASSOCIATE EDITOR

As a Tier One automotive suppli- er, Marne-MI-based Competi- tion Engineering has accelerat- ed its sales from $2 million in 1997, when it became part of the Huizenga Manufacturing Group in Grand Rapids, MI, to $20 million today. During that period, its workforce grew from 20 to 80 employees and its manufacturing space from 14,000 sq. ft. to its current 60,000-sq.-ft. facility. Here it maintains its dual product focus: sheet metal stamping dies (progressive, transfer, line and assembly dies), and sheet metal prototypes.

Such a product range calls for a diverse inventory of equipment that includes eight mechanical presses rang- ing from 150 to 1000 tons, two 1000- ton hydroforming presses, nine