Page 65 - MetalForming October 2019

P. 65

Problems Solved. On Site.

RESPECT • SUPPORT • INSPIRE

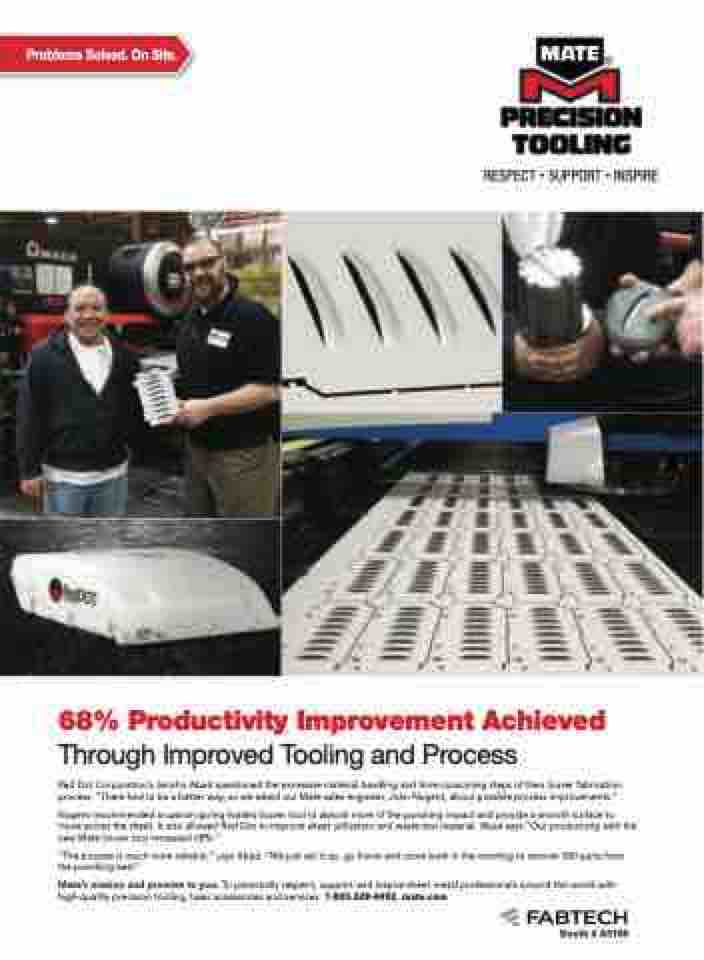

68% Productivity Improvement Achieved

Through Improved Tooling and Process

Red Dot Corporation’s Jericho Abad questioned the excessive material handling and time-consuming steps of their louver fabrication process. “There had to be a better way, so we asked our Mate sales engineer, John Nugent, about possible process improvements.”

Nugent recommended a custom spring-loaded louver tool to absorb more of the punching impact and provide a smooth surface to move across the sheet. It also allowed Red Dot to improve sheet utilization and waste less material. Abad says “Our productivity with the new Mate louver tool increased 68%.”

“The process is much more reliable,” says Abad. “We just set it up, go home and come back in the morning to remove 300 parts from the punching bed.”

Mate’s mission and promise to you: To personally respect, support and inspire sheet metal professionals around the world with high-quality precision tooling, laser accessories and services. 1-800-328-4492. mate.com

Booth # A3168