Page 40 - MetalForming August 2019

P. 40

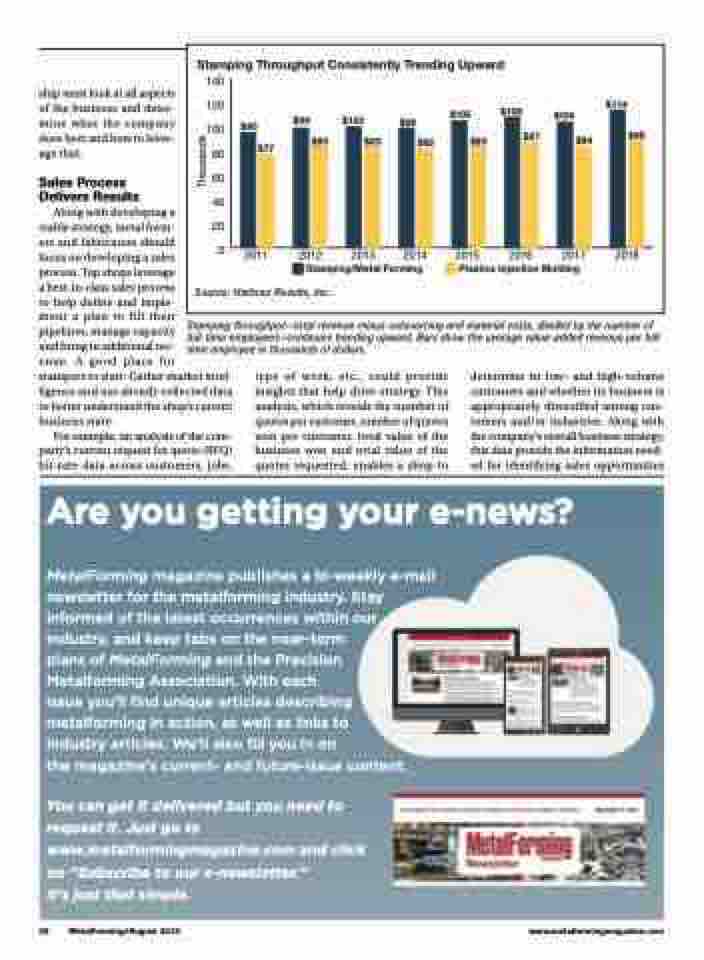

Stamping Throughput Consistently Trending Upward

140 120 100

80 60 40 20

0

$114 $87 $84 $88

2016 2017 2018

$95 $77

$99 $83

2012

$100 $83

2013

$99 $82

2014

$105 $83

2015

$108 $104

2011

Source: Harbour Results, Inc.

Stamping/Metal Forming

Plastics Injection Molding

ship must look at all aspects of the business and deter- mine what the company does best and how to lever- age that.

Sales Process Delivers Results

Along with developing a

viable strategy, metal form-

ers and fabricators should

focus on developing a sales

process. Top shops leverage

a best-in-class sales process

to help define and imple-

ment a plan to fill their

pipelines, manage capacity

and bring in additional rev-

enue. A good place for

stampers to start: Gather market intel- ligence and use already collected data to better understand the shop’s current business state.

For example, an analysis of the com- pany’s current request for quote (RFQ) hit-rate data across customers, jobs,

Stamping throughput—total revenue minus outsourcing and material costs, divided by the number of full-time employees—continues trending upward. Bars show the average value-added revenue per full- time employee in thousands of dollars.

type of work, etc., could provide insights that help drive strategy. This analysis, which reveals the number of quotes per customer, number of quotes won per customer, total value of the business won and total value of the quotes requested, enables a shop to

determine its low- and high-volume customers and whether its business is appropriately diversified among cus- tomers and/or industries. Along with the company’s overall business strategy, this data provide the information need- ed for identifying sales opportunities

Are you getting your e-news?

MetalForming magazine publishes a bi-weekly e-mail newsletter for the metalforming industry. Stay informed of the latest occurrences within our industry, and keep tabs on the near-term

plans of MetalForming and the Precision Metalforming Association. With each

issue you’ll find unique articles describing metalforming in action, as well as links to industry articles. We’ll also fill you in on

the magazine’s current- and future-issue content.

You can get it delivered but you need to request it. Just go to www.metalformingmagazine.com and click on “Subscribe to our e-newsletter.”

It’s just that simple.

38 MetalForming/August 2019

www.metalformingmagazine.com

Thousands