Page 7 - MetalForming-Jun-2018-issue

P. 7

Problems Solved

. On Site.

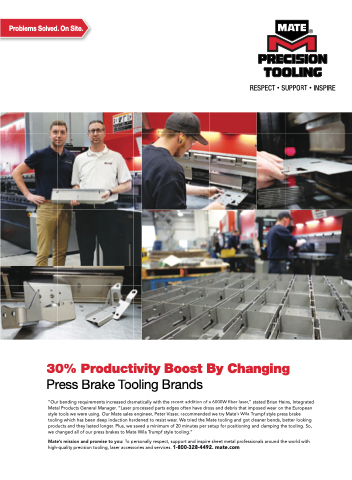

30% Productivity Boost By Changing

Press Brake Tooling Brands

“Our bending requirements increased dramatically with the recent addition of a 6000W fiber laser,” stated Brian Heins, Integrated Metal Products General Manager. “Laser processed parts edges often have dross and debris that imposed wear on the European style tools we were using. Our Mate sales engineer, Peter Visser, recommended we try Mate’s Wila Trumpf style press brake tooling which has been deep induction hardened to resist wear. We tried the Mate tooling and got cleaner bends, better looking products and they lasted longer. Plus, we saved a minimum of 20 minutes per setup for positioning and clamping the tooling. So, we changed all of our press brakes to Mate Wila Trumpf style tooling.”

Mate’s mission and promise to you: To personally respect, support and inspire sheet metal professionals around the world with high-quality precision tooling, laser accessories and services. 1-800-328-4492. mate.com

RESPECT • SUPPORT • INSPIRE