Page 20 - MetalForming-Apr-2018-issue

P. 20

The Science of Forming By Daniel J. Schaeffler, Ph.D.

Know Your Sheetmetal— Aluminum-Alloy Terminology

Aluminum alloys are categorized by a four-digit code. The first digit indicates the main element or elements alloyed with aluminum to produce the specific grade. Products with the same first digit are said to be in the same series or family, described by a number followed by three zeroes or “X”s, such as 5000-series or 6XXX- series aluminum. Within the same series, products share basic character- istics and applications.

Beverage-can bodies represent the highest-volume application for 3XXX aluminum alloys, which use manganese as the primary alloying element. Man- ufacturers produce 200 billion soda and beer cans each year–more than 6000 every second. In sheet form, alloys used to produce the cans are not inherently high-strength, but the draw-and-wall- iron process used in canmaking increases strength while reducing thick- ness to about 0.1 mm. (Fun fact: Car- bonation increases the internal pressure of beverage cans—when stacked in a store display, they do not collapse. It’s even claimed that four six-packs can

Danny Schaeffler, with

30 years of materials and applications experi- ence, is co-founder of 4M Partners, LLC and founder and president of Engineering Quality Solu- tions (EQS). EQS provides product-applications assistance to materials and manufacturing com-

panies; 4M teaches fundamentals and practical details of material properties, forming technolo- gies, processes and troubleshooting needed to form high-quality components. Schaeffler, who also spent 10 years at LTV Steel Co., received his Bach- elor of Science degree in Materials Science and Engineering from the Johns Hopkins University in Baltimore, MD, and Master of Science and Doctor of Philosophy degrees in Materials Engineering from Drexel University in Philadelphia, PA.

Danny Schaeffler

248/66-STEEL • www.EQSgroup.com

E-mail ds@eqsgroup.com or Danny@learning4m.com

support a 2-ton vehicle.)

Magnesium is the main alloying ele-

ment in 5XXX-series aluminum. Alloys in this series offer good combinations of strength and formability. However, higher strength levels introduce an increasing corrosion risk, especially as temperature increases. Alloys in the 5XXX-series may form Lüders lines during deformation, which eliminates their use in exposed applications. (Another fun fact: One-third of global magnesium production is used for alloying with aluminum.)

6XXX-series aluminum uses a mag- nesium-silicon combination as the pri- mary alloying elements. Like the 5XXX- series, good combinations of strength and formability exist, but here an exposed quality surface can be pro- duced without risk of Lüders or other bands affecting the appearance.

The 7XXX-series grades feature some of the highest-strength alu- minum-sheet alloys, but typically do not offer good formability at room tem- perature. Successful stamping may require forming at temperatures at or greater than 200 C. These products usually are riveted rather than welded, owing to the risk of weld cracking from a large solidification-temperature

range. In addition to having zinc as the main alloying element, some grades also contain a combination of magne- sium and copper.

Both 6XXX- and 7XXX-series alloys strengthen following heattreatment. This allows for stamping a lower- strength product, which, following pro- cessing, converts to a higher-strength product for industrial applications. For example, in automotive applications, 6XXX grades achieve full properties after stamping followed by a paint- bake (curing) cycle of about 185 C for 20 min.

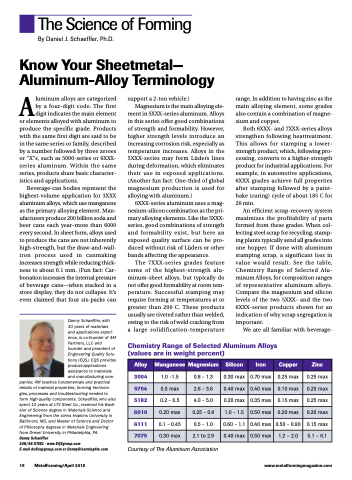

An efficient scrap-recovery system maximizes the profitability of parts formed from these grades. When col- lecting steel scrap for recycling, stamp- ing plants typically send all grades into one hopper. If done with aluminum stamping scrap, a significant loss in value would result. See the table, Chemistry Range of Selected Alu- minum Alloys, for composition ranges of representative aluminum alloys. Compare the magnesium and silicon levels of the two 5XXX- and the two 6XXX-series products shown for an indication of why scrap segregation is important.

We are all familiar with beverage-

Chemistry Range of Selected Aluminum Alloys (values are in weight percent)

Alloy

Manganese

Magnesium

Silicon

Iron

Copper

Zinc

3004

1.0 -1.5

0.8 - 1.3

0.30 max

0.70 max

0.25 max

0.25 max

5754

0.5 max

2.6 - 3.6

0.40 max

0.40 max

0.10 max

0.20 max

5182

0.2 - 0.5

4.0 - 5.0

0.20 max

0.35 max

0.15 max

0.25 max

6016

0.20 max

0.25 - 0.6

1.0 - 1.5

0.50 max

0.20 max

0.20 max

6111

0.1 - 0.45

0.5 - 1.0

0.60 - 1.1

0.40 max

0.50 - 0.90

0.15 max

7075

0.30 max

2.1 to 2.9

0.40 max

0.50 max

1.2 – 2.0

5.1 – 6.1

18 MetalForming/April 2018

www.metalformingmagazine.com

Courtesy of The Aluminum Association