Page 56 - MetalForming-Mar-2018-issue

P. 56

The Science of Forming By Daniel J. Schaeffler, Ph.D.

Know Your Sheetmetal Terminology–Part 2

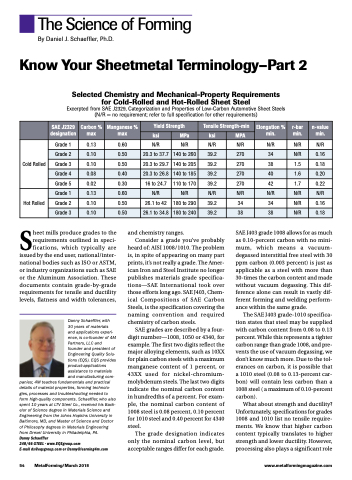

Selected Chemistry and Mechanical-Property Requirements

for Cold-Rolled and Hot-Rolled Sheet Steel

Excerpted from SAE J2329, Categorization and Properties of Low-Carbon Automotive Sheet Steels (N/R = no requirement; refer to full specification for other requirements)

SAE J2329 designation

Carbon % max

Manganese % max

Yield Strength

Tensile Strength-min

Elongation % min.

r-bar min.

n-value min.

ksi

MPa

ksi

MPA

Cold Rolled

Grade 1

0.13

0.60

N/R

N/R

N/R

N/R

N/R

N/R

N/R

Grade 2

0.10

0.50

20.3 to 37.7

140 to 260

39.2

270

34

N/R

0.16

Grade 3

0.10

0.50

20.3 to 29.7

140 to 205

39.2

270

38

1.5

0.18

Grade 4

0.08

0.40

20.3 to 26.8

140 to 185

39.2

270

40

1.6

0.20

Grade 5

0.02

0.30

16 to 24.7

110 to 170

39.2

270

42

1.7

0.22

Hot Rolled

Grade 1

0.13

0.60

N/R

N/R

N/R

N/R

N/R

N/R

N/R

Grade 2

0.10

0.50

26.1 to 42

180 to 290

39.2

34

34

N/R

0.16

Grade 3

0.10

0.50

26.1 to 34.8

180 to 240

39.2

38

38

N/R

0.18

Sheet mills produce grades to the requirements outlined in speci- fications, which typically are issued by the end user, national/inter- national bodies such as ISO or ASTM, or industry organizations such as SAE or the Aluminum Association. These documents contain grade-by-grade requirements for tensile and ductility levels, flatness and width tolerances,

Danny Schaeffler, with

30 years of materials and applications experi- ence, is co-founder of 4M Partners, LLC and founder and president of Engineering Quality Solu- tions (EQS). EQS provides product-applications assistance to materials and manufacturing com-

panies; 4M teaches fundamentals and practical details of material properties, forming technolo- gies, processes and troubleshooting needed to form high-quality components. Schaeffler, who also spent 10 years at LTV Steel Co., received his Bach- elor of Science degree in Materials Science and Engineering from the Johns Hopkins University in Baltimore, MD, and Master of Science and Doctor of Philosophy degrees in Materials Engineering from Drexel University in Philadelphia, PA.

Danny Schaeffler

248/66-STEEL • www.EQSgroup.com

E-mail ds@eqsgroup.com or Danny@learning4m.com

and chemistry ranges.

Consider a grade you’ve probably

heard of: AISI 1008/1010. The problem is, in spite of appearing on many part prints, it’s not really a grade. The Amer- ican Iron and Steel Institute no longer publishes materials grade specifica- tions—SAE International took over those efforts long ago. SAE J403, Chem- ical Compositions of SAE Carbon Steels, is the specification covering the naming convention and required chemistry of carbon steels.

SAE grades are described by a four- digit number—1008, 1050 or 4340, for example. The first two digits reflect the major alloying elements, such as 10XX for plain carbon steels with a maximum manganese content of 1 percent, or 43XX used for nickel-chromium- molybdenum steels. The last two digits indicate the nominal carbon content in hundredths of a percent. For exam- ple, the nominal carbon content of 1008 steel is 0.08 percent, 0.10 percent for 1010 steel and 0.40 percent for 4340 steel.

The grade designation indicates only the nominal carbon level, but acceptable ranges differ for each grade.

SAE J403 grade 1008 allows for as much as 0.10-percent carbon with no mini- mum, which means a vacuum- degassed interstitial free steel with 30 ppm carbon (0.003 percent) is just as applicable as a steel with more than 30-times the carbon content and made without vacuum degassing. This dif- ference alone can result in vastly dif- ferent forming and welding perform- ance within the same grade.

The SAE J403 grade-1010 specifica- tion states that steel may be supplied with carbon content from 0.08 to 0.13 percent. While this represents a tighter carbon range than grade 1008, and pre- vents the use of vacuum degassing, we don’t know much more. Due to the tol- erances on carbon, it is possible that a 1010 steel (0.08 to 0.13-percent car- bon) will contain less carbon than a 1008 steel ( a maximum of 0.10-percent carbon).

What about strength and ductility? Unfortunately, specifications for grades 1008 and 1010 list no tensile require- ments. We know that higher carbon content typically translates to higher strength and lower ductility. However, processing also plays a significant role

54 MetalForming/March 2018

www.metalformingmagazine.com