Page 34 - MetalForming-Feb-2018-issue

P. 34

FABRICATION

Solid-Wire Welding Advancements

...but does a perfect filler wire exist?

BY JOSE LUIS BERMUDEZ

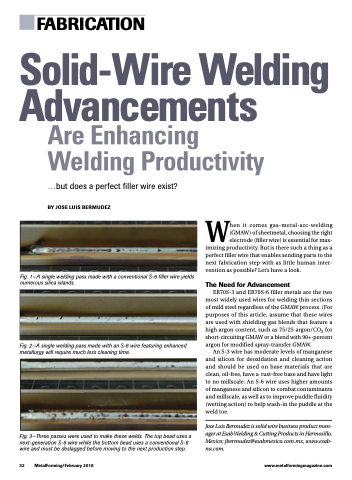

Fig. 1—A single welding pass made with a conventional S-6 filler wire yields numerous silica islands.

Fig. 2—A single welding pass made with an S-6 wire featuring enhanced metallurgy will require much less cleaning time.

When it comes gas-metal-arc-welding (GMAW) of sheetmetal, choosing the right electrode (filler wire) is essential for max- imizing productivity. But is there such a thing as a perfect filler wire that enables sending parts to the next fabrication step with as little human inter- vention as possible? Let’s have a look.

The Need for Advancement

ER70S-3 and ER70S-6 filler metals are the two most widely used wires for welding thin sections of mild steel regardless of the GMAW process. (For purposes of this article, assume that these wires are used with shielding gas blends that feature a high argon content, such as 75/25 argon/CO2 for short-circuiting GMAW or a blend with 90+-percent argon for modified spray-transfer GMAW.

An S-3 wire has moderate levels of manganese and silicon for deoxidation and cleaning action and should be used on base materials that are clean, oil-free, have a rust-free base and have light to no millscale. An S-6 wire uses higher amounts of manganese and silicon to combat contaminants and millscale, as well as to improve puddle fluidity (wetting action) to help wash-in the puddle at the weld toe.

Jose Luis Bermudez is solid wire business product man- ager at Esab Welding & Cutting Products in Hermosillo, Mexico; jbermudez@esabmexico.com.mx, www.esab- na.com.

Fig. 3—Three passes were used to make these welds. The top bead uses a next-generation S-6 wire while the bottom bead uses a conventional S-6 wire and must be deslagged before moving to the next production step.

32 MetalForming/February 2018

www.metalformingmagazine.com