Page 50 - MetalForming November 2017

P. 50

Tooling by Design

By Peter Ulintz

Deep Drawing—Advanced Topics

My past two columns addressed fundamental principles of deep drawing flat-bottom cups and rectangular boxes. But as one might expect, many deep-drawn cups and boxes do not have flat bottoms and straight walls. What’s more, nonsym- metrical cup draws are more common.

Deep-drawn cup designs may include tapered walls, hemispherical bottoms or dome-shaped bottoms. These designs have one thing in com- mon: the need for high blankholder forces. If the blankholder forces are not high enough, loose part material between the punch-face contact and the die-entry radius will not be stretched tightly over the punch face. With loose material present, buckles, puckers and wrinkles can easily form in the unsupported region.

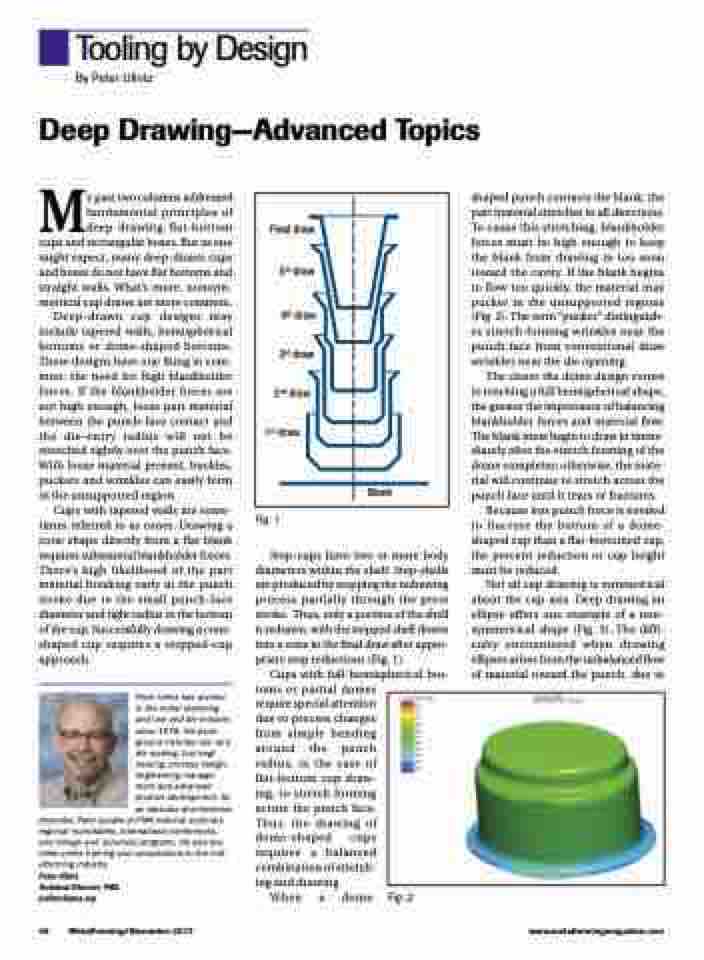

Cups with tapered walls are some- times referred to as cones. Drawing a cone shape directly from a flat blank requires substantial blankholder forces. There’s high likelihood of the part material breaking early in the punch stroke due to the small punch-face diameter and tight radius in the bottom of the cup. Successfully drawing a cone- shaped cup requires a stepped-cup approach.

Peter Ulintz has worked in the metal stamping and tool and die industry since 1978. His back- ground includes tool and die making, tool engi- neering, process design, engineering manage- ment and advanced product development. As an educator and technical

presenter, Peter speaks at PMA national seminars, regional roundtables, international conferences, and college and university programs. He also pro- vides onsite training and consultations to the met- alforming industry.

Peter Ulintz

Technical Director, PMA pulintz@pma.org

Fig. 1

Step-cups have two or more body diameters within the shell. Step-shells are produced by stopping the redrawing process partially through the press stroke. Thus, only a portion of the shell is redrawn, with the stepped shell drawn into a cone in the final draw after appro- priate step reductions (Fig. 1).

Cups with full-hemispherical bot- toms or partial domes

require special attention

due to process changes

shaped punch contacts the blank, the part material stretches in all directions. To cause this stretching, blankholder forces must be high enough to keep the blank from drawing in too soon toward the cavity. If the blank begins to flow too quickly, the material may pucker in the unsupported regions (Fig. 2). The term “pucker” distinguish- es stretch-forming wrinkles near the punch face from conventional draw wrinkles near the die opening.

The closer the dome design comes to reaching a full hemispherical shape, the greater the importance of balancing blankholder forces and material flow. The blank must begin to draw in imme- diately after the stretch forming of the dome completes; otherwise, the mate- rial will continue to stretch across the punch face until it tears or fractures.

Because less punch force is needed to fracture the bottom of a dome- shaped cup than a flat-bottomed cup, the percent reduction or cup height must be reduced.

Not all cup drawing is symmetrical about the cup axis. Deep drawing an ellipse offers one example of a non- symmetrical shape (Fig. 3). The diffi- culty encountered when drawing ellipses arises from the unbalanced flow of material toward the punch, due to

Final draw

5th draw

4th draw 3rd draw

2nd draw 1st draw

Blank

48 MetalForming/November 2017

www.metalformingmagazine.com

from simple bending around the punch radius, in the case of flat-bottom cup draw- ing, to stretch forming across the punch face. Thus, the drawing of dome-shaped cups requires a balanced combination of stretch- ing and drawing.

When a

Fig. 2

dome-