Page 32 - MetalForming September 2017

P. 32

Panel Bending

Schools the Competition

This Chicago fabricator leverages technology to solidify itself as a top supplier of carts, furniture and more

to K-through-12 educational customers.

BY LOUIS A. KREN, SENIOR EDITOR

“Rework and reimagine,” is how the Bretford Man- ufacturing website describes this 200-plus- employee Franklin Park, IL, fabricating and

assembly company, which builds education-based mobile carts and furniture in its 325,000-sq.-ft. manufacturing oper- ation, and delivers these products worldwide. The description is on point, as the company constantly develops new, tech- nologically advanced offerings—years ago it was reportedly the first to offer mobile computer carts, the first to build a comprehensive line of audio/visual accessories and the first to launch a power-managing cart that conserves laptop bat- tery life.

“We service mainly kindergarten through 12th grade, and when schools let out, our business increases,” says Dave Raddatz, plant manager at Bretford. “We’ll work two 10-hr. shifts during the summer to meet demand.”

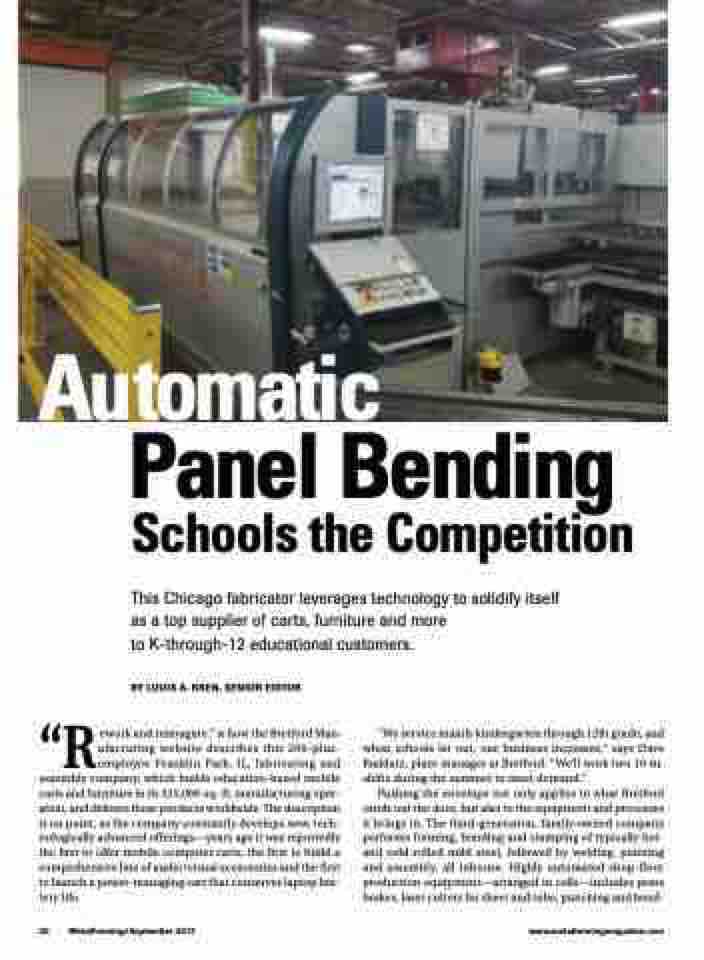

Pushing the envelope not only applies to what Bretford sends out the door, but also to the equipment and processes it brings in. The third-generation, family-owned company performs forming, bending and stamping of typically hot- and cold-rolled mild steel, followed by welding, painting and assembly, all inhouse. Highly automated shop-floor production equipment—arranged in cells—includes press brakes, laser cutters for sheet and tube, punching and bend-

30 MetalForming/September 2017

www.metalformingmagazine.com

Automatic