Page 36 - MetalForming August 2017

P. 36

Press Feeds

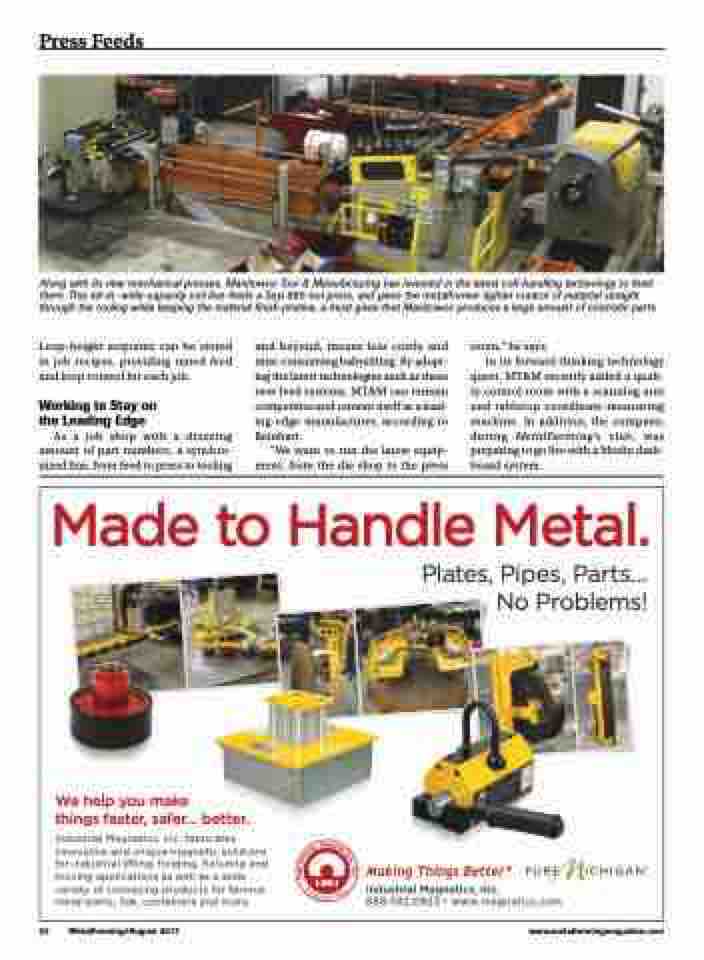

Along with its new mechanical presses, Manitowoc Tool & Manufacturing has invested in the latest coil-handling technology to feed them. This 48-in.-wide-capacity coil line feeds a Seyi 660-ton press, and gives the metalformer tighter control of material straight through the tooling while keeping the material finish pristine, a must given that Manitowoc produces a large amount of cosmetic parts.

Loop-height setpoints can be stored in job recipes, providing tuned feed and loop control for each job.

Working to Stay on the Leading Edge

As a job shop with a dizzying amount of part numbers, a synchro- nized line, from feed to press to tooling

and beyond, means less costly and time-consuming babysitting. By adopt- ing the latest technologies such as these new feed systems, MT&M can remain competitive and cement itself as a lead- ing-edge manufacturer, according to Reinhart.

“We want to run the latest equip- ment, from the die shop to the press

room,” he says.

In its forward-thinking technology

quest, MT&M recently added a quali- ty-control room with a scanning arm and tabletop coordinate-measuring machine. In addition, the company, during MetalForming’s visit, was preparing to go live with a Merlin dash- board system.

Made to Handle Metal.

We help you make

things faster, safer... better.

Industrial Magnetics, Inc. fabricates innovative and unique magnetic solutions for industrial lifting, holding, fixturing and moving applications as well as a wide variety of conveying products for ferrous metal parts, lids, containers and more.

Plates, Pipes, Parts... No Problems!

Industrial Magnetics, Inc.

888.582.0823 • www.magnetics.com

34 MetalForming/August 2017

www.metalformingmagazine.com