Page 12 - MetalForming August 2017

P. 12

Tech Update

New Laser-Cutting Processes Deliver Higher Speeds, Use Less Gas

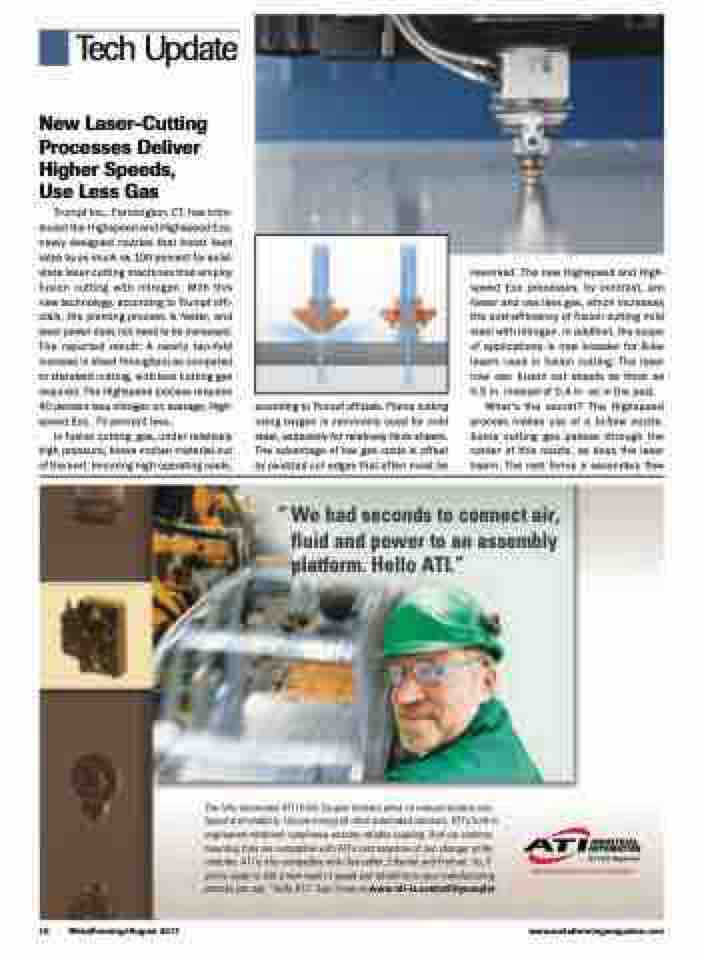

Trumpf Inc., Farmington, CT, has intro- duced the Highspeed and Highspeed Eco, newly designed nozzles that boost feed rates by as much as 100 percent for solid- state laser-cutting machines that employ fusion cutting with nitrogen. With this new technology, according to Trumpf offi- cials, the piercing process is faster, and laser power does not need to be increased. The reported result: A nearly two-fold increase in sheet throughput as compared to standard cutting, with less cutting gas required. The Highspeed process requires 40 percent less nitrogen on average; High- speed Eco, 70 percent less.

reworked. The new Highspeed and High- speed Eco processes, by contrast, are faster and use less gas, which increases the cost-efficiency of fusion-cutting mild steel with nitrogen. In addition, the scope of applications is now broader for 8-kw lasers used in fusion cutting. The laser now can fusion cut sheets as thick as 0.5 in. instead of 0.4 in. as in the past.

In fusion cutting, gas, under relatively high pressure, blows molten material out of the kerf, incurring high operating costs,

according to Trumpf officials. Flame cutting using oxygen is commonly used for mild steel, especially for relatively thick sheets. The advantage of low gas costs is offset by oxidized cut edges that often must be

“ We had seconds to connect air, fluid and power to an assembly platform. Hello ATI.”

What’s the secret? The Highspeed process makes use of a bi-flow nozzle. Some cutting gas passes through the center of this nozzle, as does the laser beam. The rest forms a secondary flow

The fully automated ATI Utility Coupler delivers what no manual solution can. Speed and reliability. Unique among all other automated solutions, ATI’s built-in engineered rotational compliance ensures reliable coupling. And our common mounting flats are compatible with ATI’s vast selection of tool changer utility modules. ATI is also compatible with DeviceNet, Ethernet and Profinet. So, if you’re ready to add a new level of speed and reliability to your manufacturing process just say, “Hello ATI.” See it now at www.ati-ia.com/utilitycoupler.

10 MetalForming/August 2017

www.metalformingmagazine.com