Page 53 - MetalForming May 2017

P. 53

Tooling by Design

[0.080 in. x 56,000 psi x (3.14 x 4.00 in.)] /2000 + BHF

Drawing force = 28 tons + 8.4 tons BHF (30 percent of punch force) = 36.4 tons

Total blanking and drawing force = 73.15 tons

After calculating the required blanking and drawing forces, it becomes necessary to compare the results with the de-rated tonnage for the press being used.

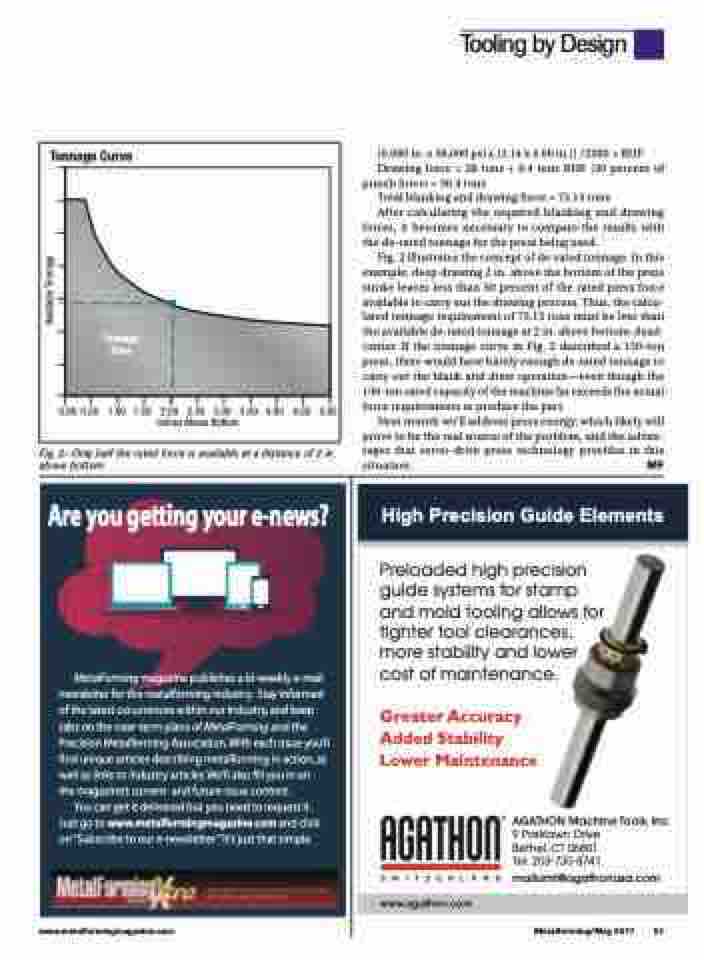

Fig. 2 illustrates the concept of de-rated tonnage. In this example, deep drawing 2 in. above the bottom of the press

Tonnage Curve

Fig. 2—Only half the rated force is available at a distance of 2 in. above bottom.

stroke leaves less than 50 percent of the rated press force

s within our industry,

to

available to carry out the drawing process. Thus, the calcu- lated tonnage requirement of 73.15 tons must be less than the available de-rated tonnage at 2 in. above bottom-dead- center. If the tonnage curve in Fig. 2 described a 150-ton press, there would have barely enough de-rated tonnage to carry out the blank and draw operation—even though the 150-ton rated capacity of the machine far exceeds the actual force requirements to produce the part.

Next month we’ll address press energy, which likely will prove to be the real source of the problem, and the advan- tages that servo-drive press technology provides in this situation. MF

Are you getting your e-news?

MetalForming magazine publishes a bi-weekly e-mail newsletter for the metalforming industry. Stay informed of the latest occurrences within our industry, and keep tabs on the near-term plans of MetalForming and the Precision Metalforming Association.With each issue you’ll find unique articles describing metalforming in action, as well as links to industry articles.We’ll also fill you in on the magazine’s current- and future-issue content.

You can get it delivered but you need to request it. Just go to www.metalformingmagazine.com and click on“Subscribe to our e-newsletter.”It’s just that simple.

High Precision Guide Elements

Preloaded high precision guide systems for stamp and mold tooling allows for tighter tool clearances, more stability and lower cost of maintenance.

Greater Accuracy Added Stability Lower Maintenance

AGATHON Machine Tools, Inc

9 Parklawn Drive Bethel, CT 06801 Tel: 203-730-8741

mailamt@agathonusa.com

www.agathon.com

www.metalformingmagazine.com

MetalForming/May 2017 51

a

w

ce

o

0.00 0.50 1.00 1.50 2.00 2.50 3.00 3.50 4.00 4.50 5.00 Inches Above Bottom

Tonnage Zone

Stay informed of the latest occurren

Just

Available Tonnage

g