Page 41 - MetalForming March 2017

P. 41

we found that the coatings weren’t holding up,” explains Ken Bateman, vice president of manufacturing at Uni- versal, who, along with Jim Harsa, sen- ior tool designer, detailed the compa- ny’s tool challenges with MetalForming. “So, we began researching other coat- ings as well as the tool steel itself. Even with higher-quality steels, we still couldn’t overcome the tool wear when forming HSLA. For the clutch discs and related parts, a lot of shaving and extru- sion is performed with the tooling to form pockets. For the door hinges, which shifted to stronger material in order to support heavier refrigerator doors while maintaining a low profile, we run higher volumes, to 100,000 pieces, and the HSLA was pretty abra- sive against the tooling.”

Tool Coating Proves Effective

Back in 2004, Universal first identi- fied a tool-coating process from Phygen Coatings Inc., Minneapolis, MN, as a possible remedy, after testing other coatings applied at both high and low temperatures.

“The first time we used it was for an emergency-brake bracket that necessitated vertical wiping, the form- ing of ribs and requirements for tight tolerances on a 190-deg. draw,” Bate- man says. “Nothing would hold up until we identified the coating process from Phygen.”

How did the new coating work?

“We went from worn out forms and gouging after forming 10,000 pieces,” recalls Bateman, “to being able to pro- duce as many as 200,000 pieces before recoating. The difference was night and day.”

Phygen applies its patented FortiPhy physical vapor deposition technology to create a thin and dense nanocrys- talline coating structure onto any tool- steel substrate. Described by Phygen president Dave Bell, the process creates a high level of adhesion. And, it does so without pulling carbon from the tools.

Temperature also varies among the various tool-coating processes. Chem- ical-vapor-deposition coatings and

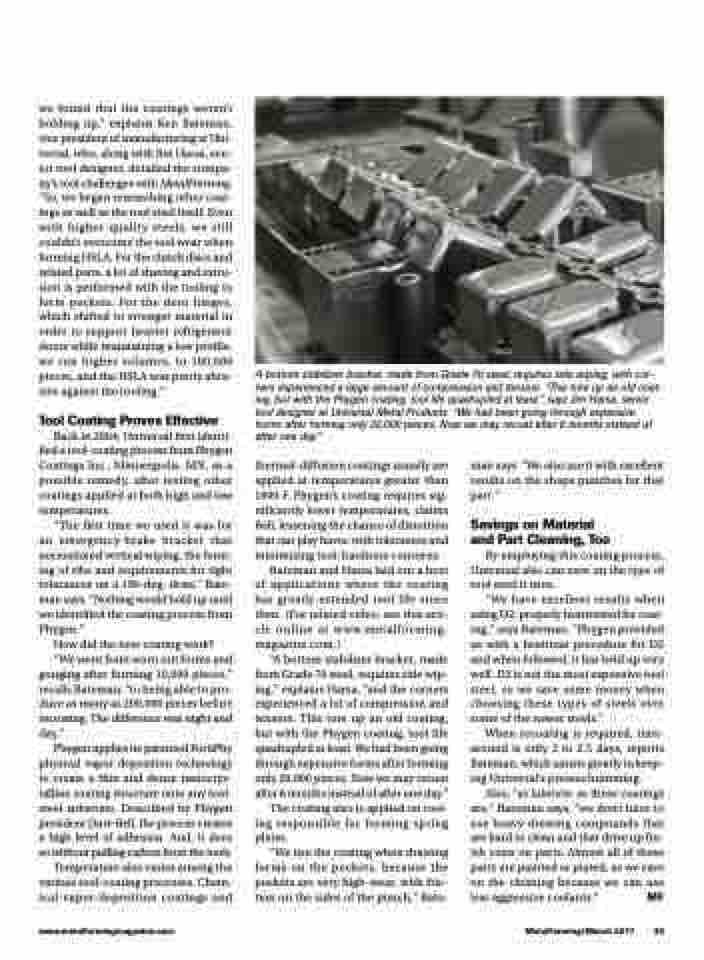

A bottom stabilizer bracket, made from Grade 70 steel, requires side wiping, with cor- ners experienced a large amount of compression and tension. “This tore up an old coat- ing, but with the Phygen coating, tool life quadrupled at least,” says Jim Harsa, senior tool designer at Universal Metal Products. “We had been going through expensive forms after forming only 20,000 pieces. Now we may recoat after 6 months instead of after one day.”

www.metalformingmagazine.com

MetalForming/March 2017 39

thermal-diffusion coatings usually are applied at temperatures greater than 1800 F. Phygen’s coating requires sig- nificantly lower temperatures, claims Bell, lessening the chance of distortion that can play havoc with tolerances and minimizing tool-hardness concerns.

Bateman and Harsa laid out a host of applications where the coating has greatly extended tool life since then. (For related video, see this arti- cle online at www.metalforming- magazine.com.)

“A bottom stabilizer bracket, made from Grade 70 steel, requires side wip- ing,” explains Harsa, “and the corners experienced a lot of compression and tension. This tore up an old coating, but with the Phygen coating, tool life quadrupled at least. We had been going through expensive forms after forming only 20,000 pieces. Now we may recoat after 6 months instead of after one day.”

The coating also is applied on tool- ing responsible for forming spring plates.

“We use the coating when drawing forms on the pockets, because the pockets are very high-wear, with fric- tion on the sides of the punch,” Bate-

man says. “We also use it with excellent results on the shape punches for that part.”

Savings on Material and Part Cleaning, Too

By employing this coating process, Universal also can save on the type of tool steel it uses.

“We have excellent results when using D2, properly heattreated for coat- ing,” says Bateman. “Phygen provided us with a heattreat procedure for D2 and when followed, it has held up very well. D2 is not the most expensive tool steel, so we save some money when choosing these types of steels over some of the newer steels.”

When recoating is required, turn- around is only 2 to 2.5 days, reports Bateman, which assists greatly in keep- ing Universal’s presses humming.

Also, “as lubristic as these coatings are,” Bateman says, “we don’t have to use heavy drawing compounds that are hard to clean and that drive up fin- ish costs on parts. Almost all of these parts are painted or plated, so we save on the cleaning because we can use less aggressive coolants.” MF