Page 28 - MetalForming February 2017

P. 28

Waterjet Cutting:

Take a Closer Look

For fabricators of metal and beyond, these machines deliver flexibility and performance at reasonable costs. And they’re more dependable than ever.

BY LOUIS A. KREN, SENIOR EDITOR

Technology Improvement

At one time, waterjet cutters did exactly that–cut via a pressurized water stream. Wood and softer materials were the main applications. By the 1990s, as systems incorporated abrasive into the waterjet streams, the technology became more common in metal-fab- rication shops, where the use of garnet enabled more rapid cutting of harder and thicker materials. A common per- ception then, and still somewhat held today, was that waterjet-cutting sys- tems were unreliable, owing to prob- lems with pumps and nozzles, and issues with system leaks.

“The dependability of waterjet-cut- ting machines was a big question mark for fabricators,” says Dumas. “There was the perception of high-maintenance systems that experienced excessive

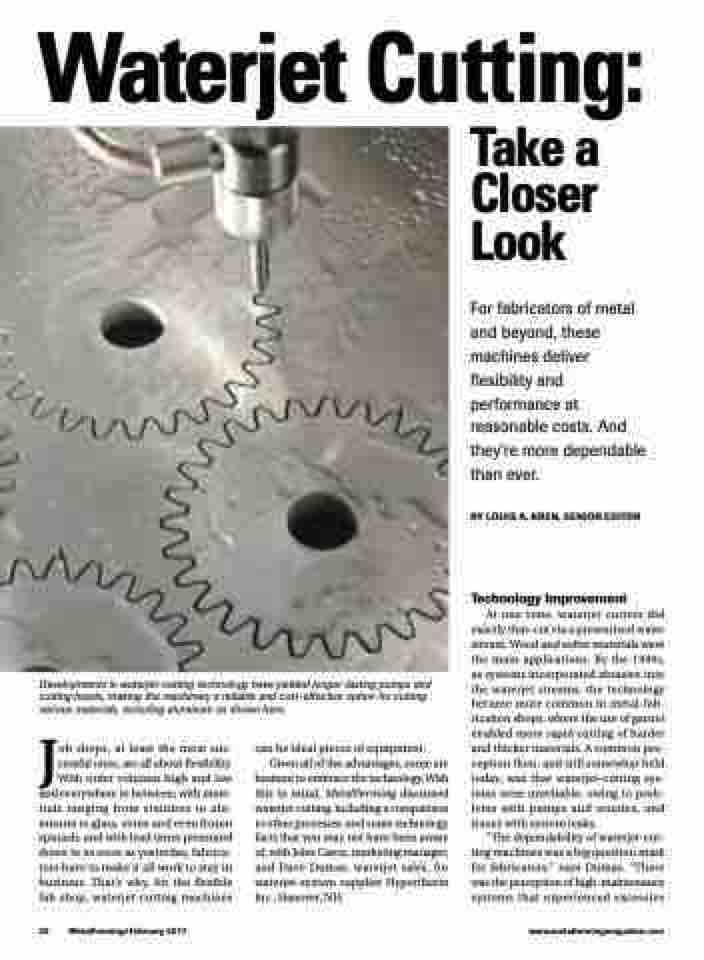

Developments in waterjet-cutting technology have yielded longer-lasting pumps and cutting heads, making the machinery a reliable and cost-effective option for cutting various materials, including aluminum as shown here.

Job shops, at least the most suc- cessful ones, are all about flexibility. With order volumes high and low and everywhere in between; with mate- rials ranging from stainless to alu- minum to glass, stone and even frozen spinach; and with lead times pressured down to as soon as yesterday, fabrica- tors have to make it all work to stay in business. That’s why, for the flexible fab shop, waterjet-cutting machines

can be ideal pieces of equipment. Given all of the advantages, some are hesitant to embrace the technology. With this in mind, MetalForming discussed waterjet cutting, including a comparison to other processes, and some technology facts that you may not have been aware of, with John Caron, marketing manager, and Dave Dumas, waterjet sales, for waterjet-system supplier Hypertherm

Inc., Hanover, NH.

26 MetalForming/February 2017

www.metalformingmagazine.com