Page 30 - MetalForming January 2017

P. 30

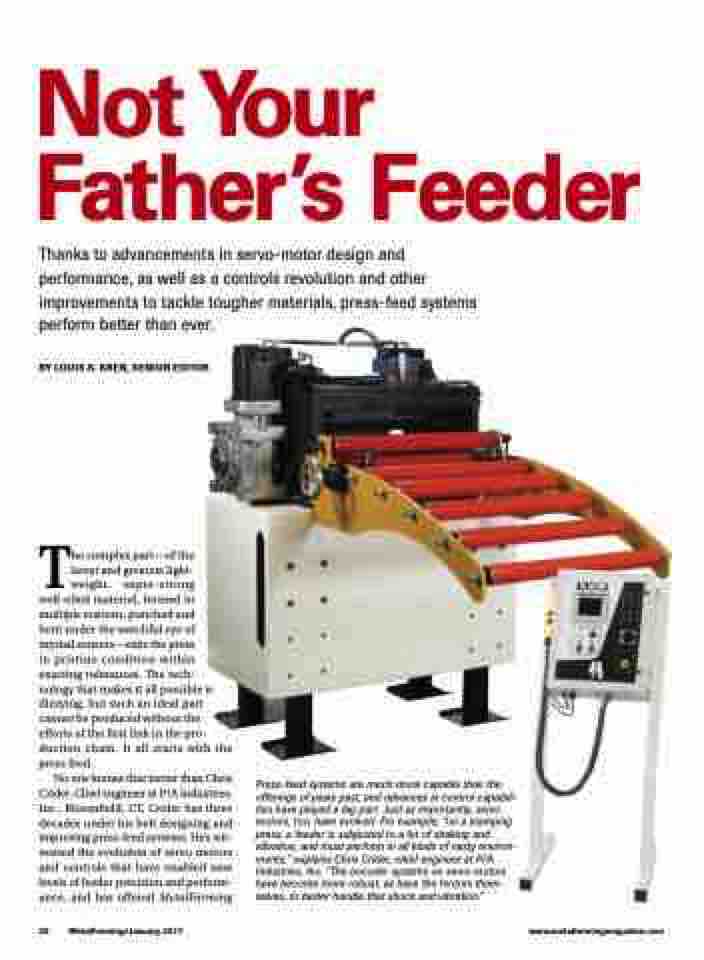

Not Your Father’s Feeder

Thanks to advancements in servo-motor design and performance, as well as a controls revolution and other improvements to tackle tougher materials, press-feed systems perform better than ever.

BY LOUIS A. KREN, SENIOR EDITOR

The complex part—of the

latest and greatest light- weight, super-strong well-oiled material, formed in multiple stations, punched and

bent under the watchful eye of myriad sensors—exits the press

in pristine condition within exacting tolerances. The tech- nology that makes it all possible is dizzying, but such an ideal part cannot be produced without the efforts of the first link in the pro- duction chain. It all starts with the press feed.

No one knows that better than Chris Crider. Chief engineer at P/A Industries, Inc., Bloomfield, CT, Crider has three decades under his belt designing and improving press-feed systems. He’s wit- nessed the evolution of servo motors and controls that have enabled new levels of feeder precision and perform- ance, and has offered MetalForming

Press-feed systems are much more capable than the offerings of years past, and advances in control capabili- ties have played a big part. Just as importantly, servo motors, too, have evolved. For example, “on a stamping press, a feeder is subjected to a lot of shaking and vibration, and must perform in all kinds of nasty environ- ments,” explains Chris Crider, chief engineer at P/A Industries, Inc. “The encoder systems on servo motors have become more robust, as have the motors them- selves, to better handle that shock and vibration.”

28 MetalForming/January 2017

www.metalformingmagazine.com