Page 46 - MetalForming November 2016

P. 46

The Science of Forming By Stuart Keeler

A Graphical Explanation of n-Value

Studying the various properties of steels and other metal alloys, one property stands out as the best and most powerful: the workhardening exponent (n-value). This property, obtained from the stress-strain curve, cannot be measured as a single point, as can tensile strength. Instead, many data points from 10- to 20-percent strain in the stress-strain curve are used to develop the n-value equation. Traditional high-strength low-alloy (HSLA) steels have used this n-value since the 1970s. For these steels, n-val- ues are mostly constant or have a nar- row range. In contrast, the n-values of advanced high-strength steels (AHSS) are constantly changing and are meas- ured and reported as the instantaneous n-value.

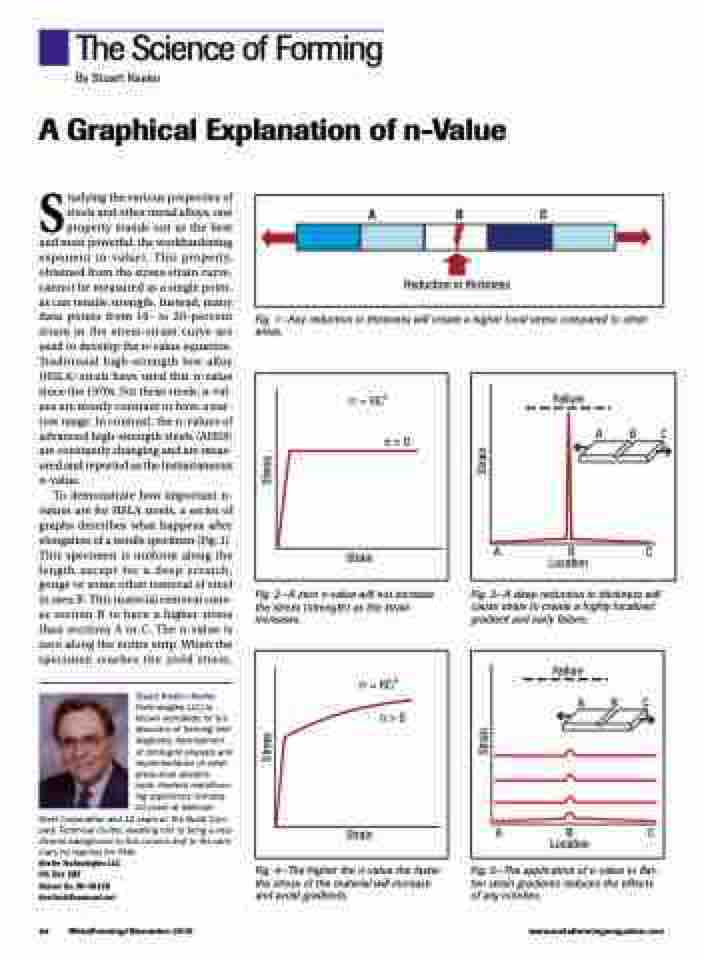

To demonstrate how important n- values are for HSLA steels, a series of graphs describes what happens after elongation of a tensile specimen (Fig. 1). This specimen is uniform along the length except for a deep scratch, gouge or some other removal of steel in area B. This material removal caus- es section B to have a higher stress than sections A or C. The n-value is zero along the entire strip. When the specimen reaches the yield stress,

Stuart Keeler (Keeler Technologies LLC) is known worldwide for his discovery of forming limit diagrams, development of circle-grid analysis and implementation of other press-shop analysis tools. Keeler’s metalform- ing experience includes 24 years at National

Steel Corporation and 12 years at The Budd Com- pany Technical Center, enabling him to bring a very diverse background to this column and to the sem- inars he teaches for PMA.

Keeler Technologies LLC P.O. Box 283

Grosse Ile, MI 48138 keeltech@comcast.net

Fig. 1—Any reduction in thickness will create a higher local stress compared to other areas.

ABC

Reduction in thickness

n= 0

Strain

Failure

ABC

ABC Location

Fig. 2—A zero n-value will not increase the stress (strength) as the strain increases.

Fig. 3—A deep reduction in thickness will cause strain to create a highly localized gradient and early failure.

n> 0

Strain

Failure ABC

ABC Location

44 MetalForming/November 2016

www.metalformingmagazine.com

Fig. 4—The higher the n-value the faster the stress of the material will increase and avoid gradients.

Fig. 5—The application of n-value to flat- ten strain gradients reduces the effects of any notches.

Stress Stress

Strain

Strain