Page 92 - MetalForming October 2016

P. 92

Much More Than Tool and Die–

One Company’s Evolution

Tooling now is just the tip of the iceberg for Reich Tool & Design. Since its

founding in 1965, the Wisconsin company has successfully added precision contract machining and, most recently, cleanroom assembly to its roster of capabilities.

BY LOUIS A. KREN, SENIOR EDITOR

In 1965, Fred Reich, experienced in the tool and die world, and his wife Judy, formed Reich Tool and Design. Back then, minding the tool- ing for OEM stamping customers— there was no shortage of them in and around Milwaukee, WI—seemed like a long-term winning proposition. In its small shop, the company built, maintained and repaired progressive, hand-transfer and regular transfer dies. The first foray outside of its core business occurred after only a few years in business, when a medical cus- tomer asked Reich to machine a few parts, using Reich Tool’s existing equipment. That began the company’s contract-machining business.

Fast forward to the mid-2000s, when some of Reich Tool’s aerospace and

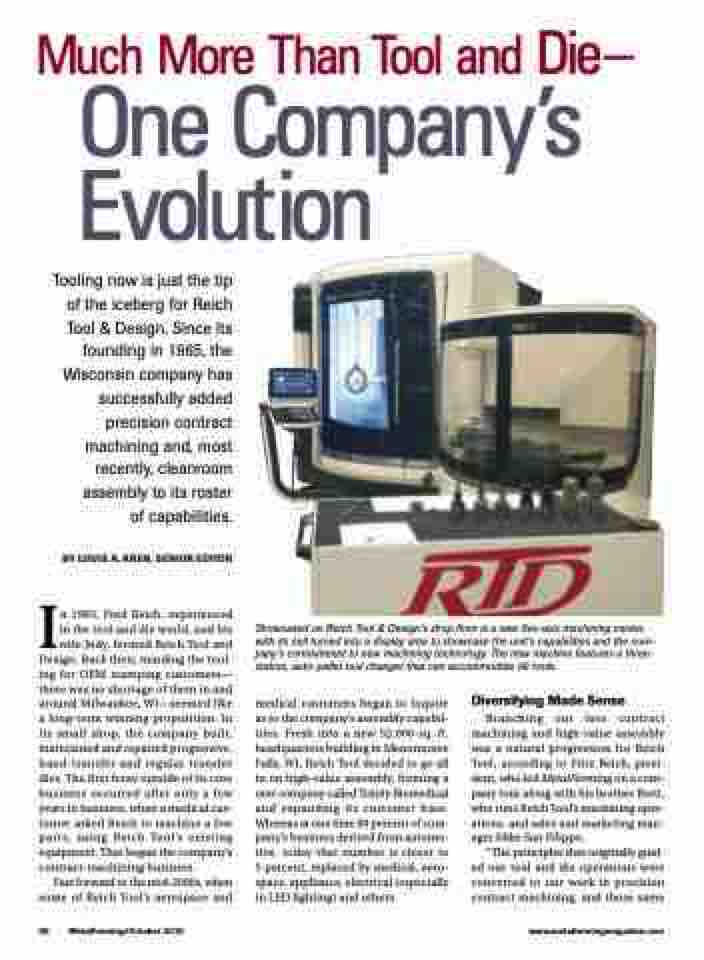

Showcased on Reich Tool & Design’s shop floor is a new five-axis machining center, with its cell turned into a display area to showcase the unit’s capabilities and the com- pany’s commitment to new machining technology. The new machine features a three- station, auto-pallet tool changer that can accommodate 90 tools.

90 MetalForming/October 2016

www.metalformingmagazine.com

medical customers began to inquire as to the company’s assembly capabil- ities. Fresh into a new 52,000-sq.-ft. headquarters building in Menomonee Falls, WI, Reich Tool decided to go all in on high-value assembly, forming a new company called Trinity Biomedical and expanding its customer base. Whereas at one time 80 percent of com- pany’s business derived from automo- tive, today that number is closer to 5 percent, replaced by medical, aero- space, appliance, electrical (especially in LED lighting) and others.

Diversifying Made Sense

Branching out into contract machining and high-value assembly was a natural progression for Reich Tool, according to Fritz Reich, presi- dent, who led MetalForming on a com- pany tour along with his brother Brett, who runs Reich Tool’s machining oper- ations, and sales and marketing man- ager Mike San Filippo.

“The principles that originally guid- ed our tool and die operations were converted to our work in precision contract machining, and those same