Page 30 - MetalForming August 2016

P. 30

Big Data

Big Data

Pays Off Big

Pays Off Big for Illinois

Fabricator

World-class on-time-delivery and quality numbers are directly related to an evolving computerized value-chain system that can automatically process as many as 5000 customer-demand changes daily across 6000 part numbers, and adjust schedules and supplier deliveries to match.

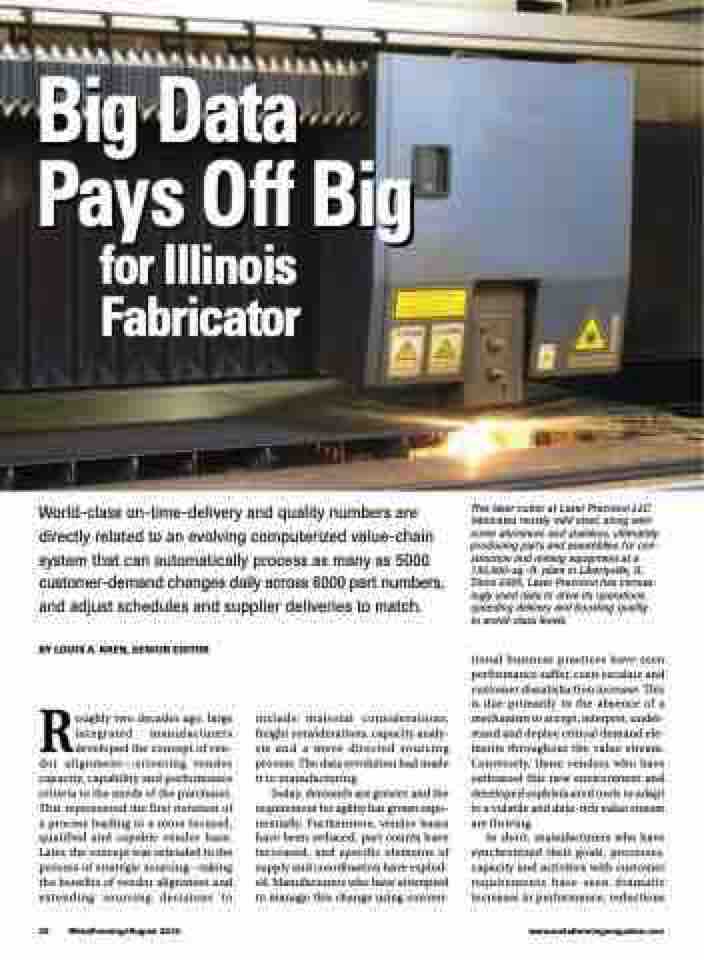

This laser cutter at Laser Precision LLC fabricates mostly mild steel, along with some aluminum and stainless, ultimately producing parts and assemblies for con- struction and mining equipment at a 130,000-sq.-ft. plant in Libertyville, IL. Since 2005, Laser Precision has increas- ingly used data to drive its operations, speeding delivery and boosting quality to world-class levels.

tional business practices have seen performance suffer, costs escalate and customer dissatisfaction increase. This is due primarily to the absence of a mechanism to accept, interpret, under- stand and deploy critical demand ele- ments throughout the value stream. Conversely, those vendors who have embraced this new environment and developed sophisticated tools to adapt to a volatile and data-rich value stream are thriving.

In short, manufacturers who have synchronized their goals, processes, capacity and activities with customer requirements have seen dramatic increases in performance, reductions

BY LOUIS A. KREN, SENIOR EDITOR

Roughly two decades ago, large integrated manufacturers developed the concept of ven- dor alignment—orienting vendor capacity, capability and performance criteria to the needs of the purchaser. This represented the first iteration of a process leading to a more focused, qualified and capable vendor base. Later, the concept was extended to the process of strategic sourcing—taking the benefits of vendor alignment and extending sourcing decisions to

include material considerations, freight considerations, capacity analy- sis and a more directed sourcing process. The data revolution had made it to manufacturing.

Today, demands are greater and the requirement for agility has grown expo- nentially. Furthermore, vendor bases have been reduced, part counts have increased, and specific elements of supply and coordination have explod- ed. Manufacturers who have attempted to manage this change using conven-

28 MetalForming/August 2016

www.metalformingmagazine.com