Page 40 - MetalForming June 2016

P. 40

Tooling by Design

By Peter Ulintz

Progressive-Die Strip Analysis–Part 2

With progressive dies, the dis- tance between workstations is of prime concern for the diedesigner,diebuilderandpresstech- nicians. Part quality depends upon this distance—called stock pitch or die pro- gression—remaining constant through- out the stamping process.

Each time the press cycles, an auto- matic feeding system pushes or pulls a strip of material from a coil through the stations of the die. The strip feeds a predetermined distance and, through the use of pilots or locators in subse- quent stations, is precisely located. When shops fail to properly control strip progression, the die strip may exhibit distorted pilot holes, misaligned match-cuts or any number of other defects.

Die-Strip Flexing

When draw-forming a part in a pro- gressive die, the blank edge must be free to flow inward toward the die cav- ity. Accomplish this through the use of stretch-webs and stretch-carriers.

Some draw-forming processes pro- duce parts having different heights. The free flow of material and the result- ing product geometry can combine to alter the relationship between the sta-

Peter Ulintz has worked in the metal stamping and tool and die industry since 1978. His back- ground includes tool and die making, tool engi- neering, process design, engineering manage- ment and advanced product development. As an educator and technical

presenter, Peter speaks at PMA national seminars, regional roundtables, international conferences, and college and university programs. He also pro- vides onsite training and consultations to the met- alforming industry.

Peter Ulintz

Technical Director, PMA pulintz@pma.org

tion-to-station centerline of

the die and the part-to-part centerline in

the strip. This Fig. 1 causes the die

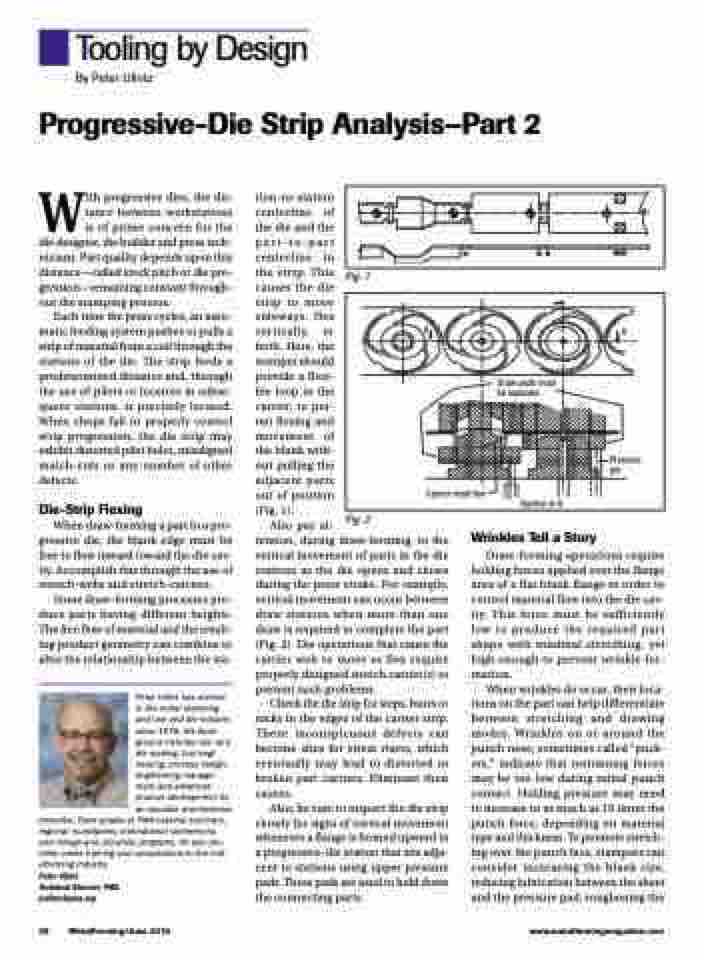

strip to move sideways, flex vertically, or both. Here, the stamper should provide a flexi- ble loop in the carrier, to per- mit flexing and movement of the blank with- out pulling the adjacent parts out of position (Fig. 1).

Also pay at- Fig. 2

tention, during draw-forming, to the vertical movement of parts in the die stations as the die opens and closes during the press stroke. For example, vertical movement can occur between draw stations when more than one draw is required to complete the part (Fig. 2). Die operations that cause the carrier web to move or flex require properly designed stretch carrier(s) to prevent such problems.

Check the die strip for steps, burrs or nicks in the edges of the carrier strip. These inconspicuous defects can become sites for stress risers, which eventually may lead to distorted or broken part carriers. Eliminate their causes.

Also, be sure to inspect the die strip closely for signs of vertical movement whenever a flange is formed upward in a progressive-die station that sits adja- cent to stations using upper pressure pads. These pads are used to hold down the connecting parts.

Wrinkles Tell a Story

Draw-forming operations require holding forces applied over the flange area of a flat blank flange in order to control material flow into the die cav- ity. This force must be sufficiently low to produce the required part shape with minimal stretching, yet high enough to prevent wrinkle for- mation.

When wrinkles do occur, their loca- tions on the part can help differentiate between stretching and drawing modes. Wrinkles on or around the punch nose, sometimes called “puck- ers,” indicate that restraining forces may be too low during initial punch contact. Holding pressure may need to increase to as much as 10 times the punch force, depending on material type and thickness. To promote stretch- ing over the punch face, stampers can consider increasing the blank size, reducing lubrication between the sheet and the pressure pad, roughening the

A

A

Pressure pin

Carrier must flex

Draw pads must be separate

Section A-A

38 MetalForming/June 2016

www.metalformingmagazine.com