Page 32 - MetalForming June 2016

P. 32

Gantry Robot System

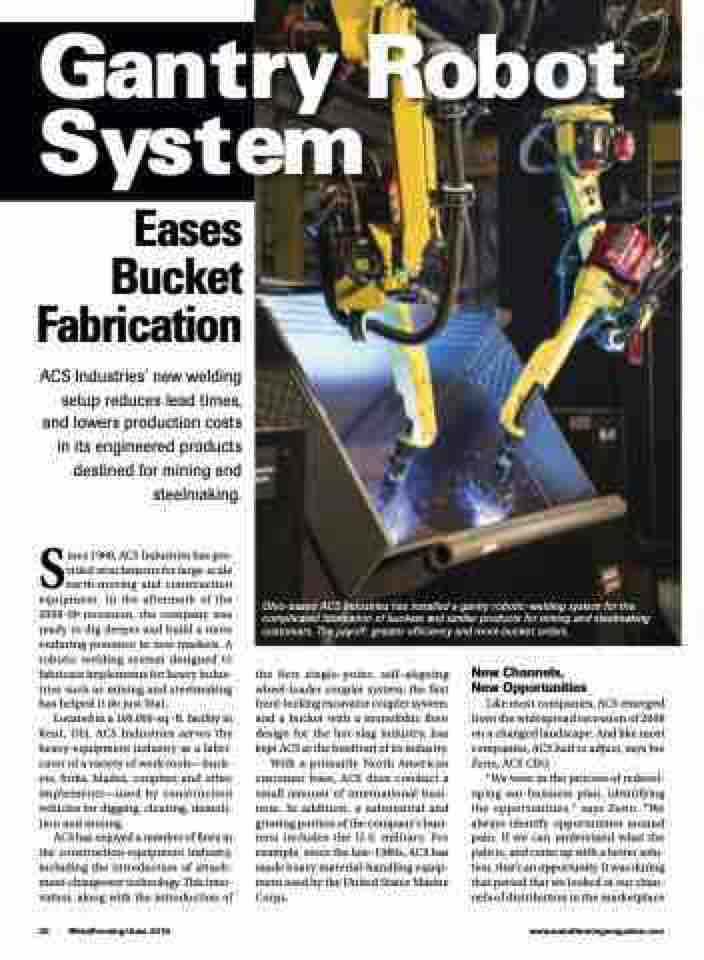

Ohio-based ACS Industries has installed a gantry robotic-welding system for the complicated fabrication of buckets and similar products for mining and steelmaking customers. The payoff: greater efficiency and more bucket orders.

Eases

Bucket

Fabrication

ACS Industries’ new welding setup reduces lead times, and lowers production costs in its engineered products destined for mining and steelmaking.

Since 1968, ACS Industries has pro- vided attachments for large-scale earth-moving and construction equipment. In the aftermath of the 2008-09 recession, the company was ready to dig deeper and build a more enduring presence in new markets. A robotic welding system designed to fabricate implements for heavy indus- tries such as mining and steelmaking has helped it do just that.

Located in a 100,000-sq.-ft. facility in Kent, OH, ACS Industries serves the heavy-equipment industry as a fabri- cator of a variety of work tools—buck- ets, forks, blades, couplers and other implements—used by construction vehicles for digging, clearing, demoli- tion and mining.

ACS has enjoyed a number of firsts in the construction-equipment industry, including the introduction of attach- ment-changeover technology. This inno- vation, along with the introduction of

the first single-point, self-aligning wheel-loader coupler system; the first front-locking excavator coupler system; and a bucket with a monolithic floor design for the hot-slag industry, has kept ACS at the forefront of its industry.

With a primarily North American customer base, ACS does conduct a small amount of international busi- ness. In addition, a substantial and growing portion of the company’s busi- ness includes the U.S. military. For example, since the late-1980s, ACS has made heavy material-handling equip- ment used by the United States Marine Corps.

New Channels, New Opportunities

Like most companies, ACS emerged from the widespread recession of 2008 on a changed landscape. And like most companies, ACS had to adjust, says Joe Zeno, ACS CEO.

“We were in the process of redevel- oping our business plan, identifying the opportunities,” says Zeno. “We always identify opportunities around pain. If we can understand what the pain is, and come up with a better solu- tion, that’s an opportunity. It was during that period that we looked at our chan- nels of distribution in the marketplace

30 MetalForming/June 2016

www.metalformingmagazine.com