Page 14 - MetalForming April 2016

P. 14

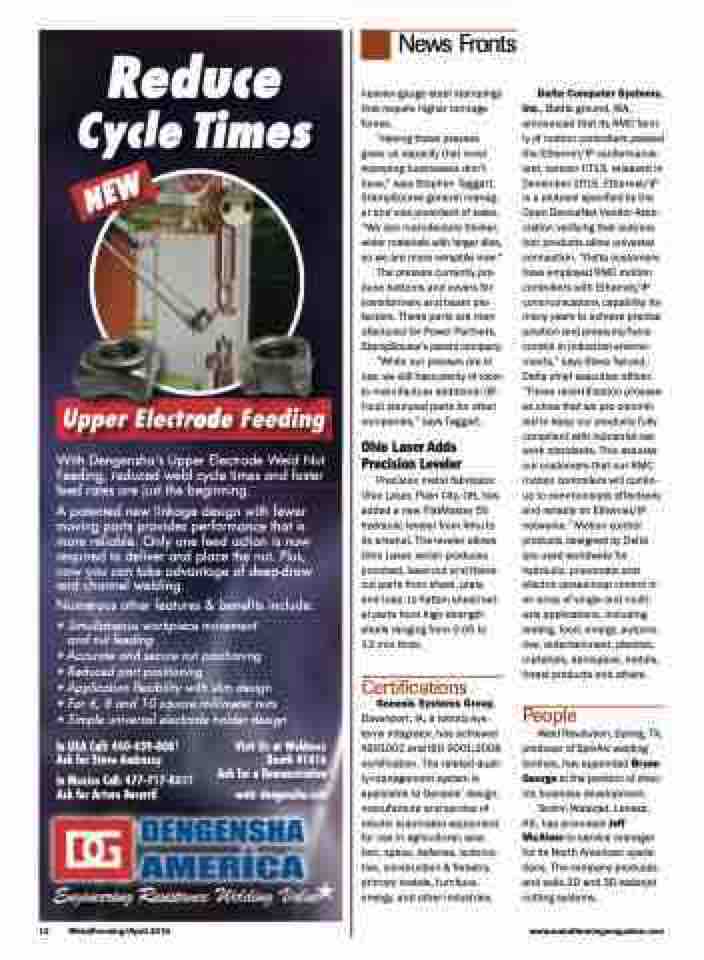

Reduce Cycle Times

News Fronts

heavier-gauge-steel stampings that require higher tonnage forces.

Delta Computer Systems, Inc., Battle ground, WA, announced that its RMC fami- ly of motion controllers passed the Ethernet/IP conformance test, version CT13, released in December 2015. Ethernet/IP is a protocol specified by the Open DeviceNet Vendor Asso- ciation verifying that automa- tion products allow universal connection. “Delta customers have employed RMC motion controllers with Ethernet/IP communications capability for many years to achieve precise position and pressure/force control in industrial environ- ments,” says Steve Nylund, Delta chief executive officer. “These recertification process- es show that we are commit- ted to keep our products fully compliant with industrial net- work standards. This assures our customers that our RMC motion controllers will contin- ue to communicate effectively and reliably on Ethernet/IP networks.” Motion-control products designed by Delta are used worldwide for hydraulic, pneumatic and electric closed-loop control in an array of single and multi- axis applications, including testing, food, energy, automo- tive, entertainment, plastics, materials, aerospace, metals, forest products and others.

“Having these presses gives us capacity that most stamping businesses don’t have,” says Stephen Taggart, StampSource general manag- er and vice president of sales. “We can manufacture thicker, wider materials with larger dies, so we are more versatile now.”

The presses currently pro- duce bottoms and covers for transformers and beam pro- tectors. These parts are man- ufactured for Power Partners, StampSource’s parent company.

Upper Electrode Feeding

With Dengensha’s Upper Electrode Weld Nut Feeding, reduced weld cycle times and faster feed rates are just the beginning.

A patented new linkage design with fewer moving parts provides performance that is more reliable. Only one feed action is now required to deliver and place the nut. Plus, now you can take advantage of deep-draw and channel welding.

Numerous other features & benefits include:

• Simultaneous workpiece movement and nut feeding

• Accurate and secure nut positioning

• Reduced part positioning

• Application flexibility with slim design

• For 6, 8 and 10 square millimeter nuts • Simple universal electrode holder design

“While our presses are in use, we still have plenty of room to manufacture additional dif- ficult stamped parts for other companies,” says Taggart.

Ohio Laser Adds Precision Leveler

Precision metal fabricator Ohio Laser, Plain City, OH, has added a new FlatMaster 55 hydraulic leveler from Arku to its arsenal. The leveler allows Ohio Laser, which produces punched, laser-cut and flame- cut parts from sheet, plate and tube, to flatten sheetmet- al parts from high-strength steels ranging from 0.05 to 12 mm thick.

Certifications

Genesis Systems Group, Davenport, IA, a robotic-sys- tems integrator, has achieved AS9100C and ISO 9001:2008 certification. The related quali- ty-management system is applicable to Genesis’ design, manufacture and service of robotic automated equipment for use in agricultural, avia- tion, space, defense, automo- tive, construction & forestry, primary metals, furniture, energy, and other industries.

People

In USA Call: 440-439-8081 Ask for Steve Andrassy

In Mexico Call: 477-717-8827 Ask for Arturo Becerril

Visit Us at Weldmex Booth #1416 Ask for a Demonstration

web: dengensha.com

Weld Revolution, Spring, TX, producer of SpinArc welding torches, has appointed Bryan George to the position of direc- tor, business development.

Techni Waterjet, Lenexa, KS, has promoted Jeff McAleer to service manager for its North American opera- tions. The company produces and sells 2D and 3D waterjet cutting systems.

12

MetalForming/April 2016

www.metalformingmagazine.com

NEW