Page 18 - MetalForming February 2016

P. 18

From

Pushbuttons

to Touchscreens

...and from two-color alphanumeric parameter displays of operating parameters presented on black backgrounds to full-color graphical LCD displays, today’s press controls provide widescreen windows into the modern-day stamping process.

BY BRAD F. KUVIN, EDITOR

Atour of the stamping-press booths at last November’s FABTECH show reveals a remarkable revolution underway: Press builders are supplying modern-day press controls that provide revealing, data-packed looks at the entire press line. They’re armed with full-color graphical displays that provide snap- shots of the entire operation as well as trending data to provide prediction capabilities.

On the pressroom floor, process visualization now intimately connects press operators to their machines. This connectivity and visualization provides up-to-the-second real-time informa- tion—press data such as tonnage, stroke position and die-protection data, as well as parameters related to feed- and transfer-systems, and other automation equipment.

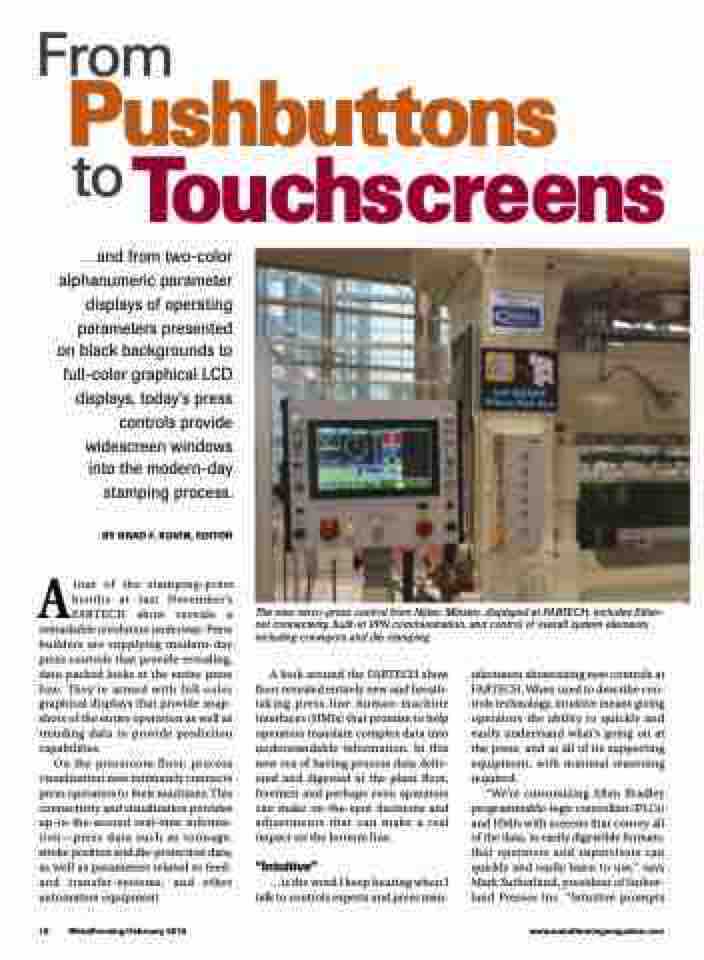

The new servo-press control from Nidec Minster, displayed at FABTECH, includes Ether- net connectivity, built-in VPN communication, and control of overall system elements including conveyors and die clamping.

16 MetalForming/February 2016

www.metalformingmagazine.com

A look around the FABTECH show floor revealed entirely new and breath- taking press-line human-machine interfaces (HMIs) that promise to help operators translate complex data into understandable information. In this new era of having process data deliv- ered and digested at the plant floor, foremen and perhaps even operators can make on-the-spot decisions and adjustments that can make a real impact on the bottom line.

“Intuitive”

...is the word I keep hearing when I talk to controls experts and press man-

ufacturers showcasing new controls at FABTECH. When used to describe con- trols technology, intuitive means giving operators the ability to quickly and easily understand what’s going on at the press, and at all of its supporting equipment, with minimal reasoning required.

“We’re customizing Allen Bradley programmable-logic controllers (PLCs) and HMIs with screens that convey all of the data, in easily digestible formats, that operators and supervisors can quickly and easily learn to use,” says Mark Sutherland, president of Suther- land Presses Inc. “Intuitive prompts